High-Temperature Trace Heater is a specialized solution designed to apply controlled electric surface heating to pipework, tanks, valves, or process equipment. Its primary function is to maintain the desired temperature by compensating for heat loss through insulation—commonly referred to as frost protection—or to increase the temperature of the target system.

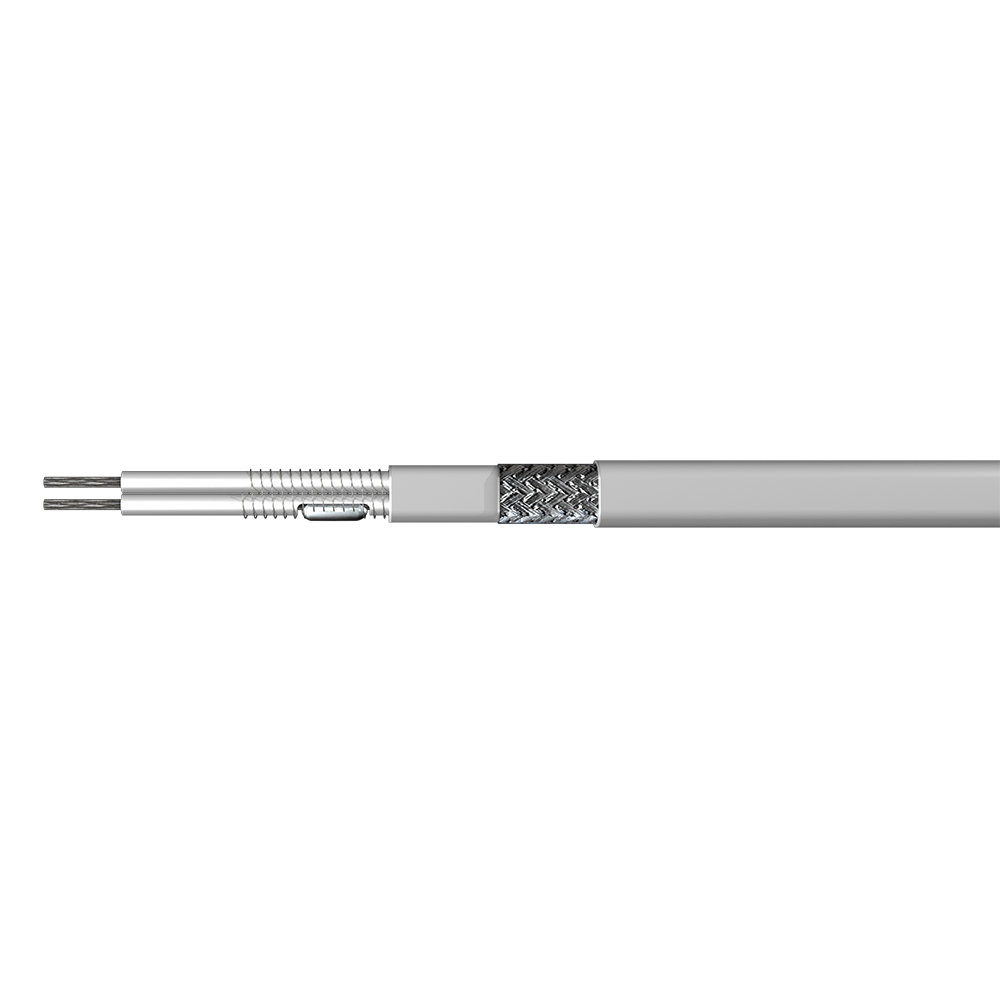

These trace heating cables consist of two parallel copper conductor wires with a resistance filament between them, creating a heating zone. When a fixed voltage is applied, a constant wattage is generated, ensuring consistent and reliable heating performance. This design allows the heating trace to withstand high temperatures, making it suitable for demanding industrial applications where elevated heat levels are required.

The High-Temperature Heating Trace is ideal for use in industries such as chemical processing, oil and gas, and manufacturing, where maintaining precise temperatures in pipelines, tanks, or equipment is critical. Its robust construction and ability to deliver uniform heat make it a dependable choice for preventing freezing, reducing viscosity in fluids, or ensuring proper process temperatures in challenging environments.

English

English русский

русский Français

Français Español

Español عربى

عربى