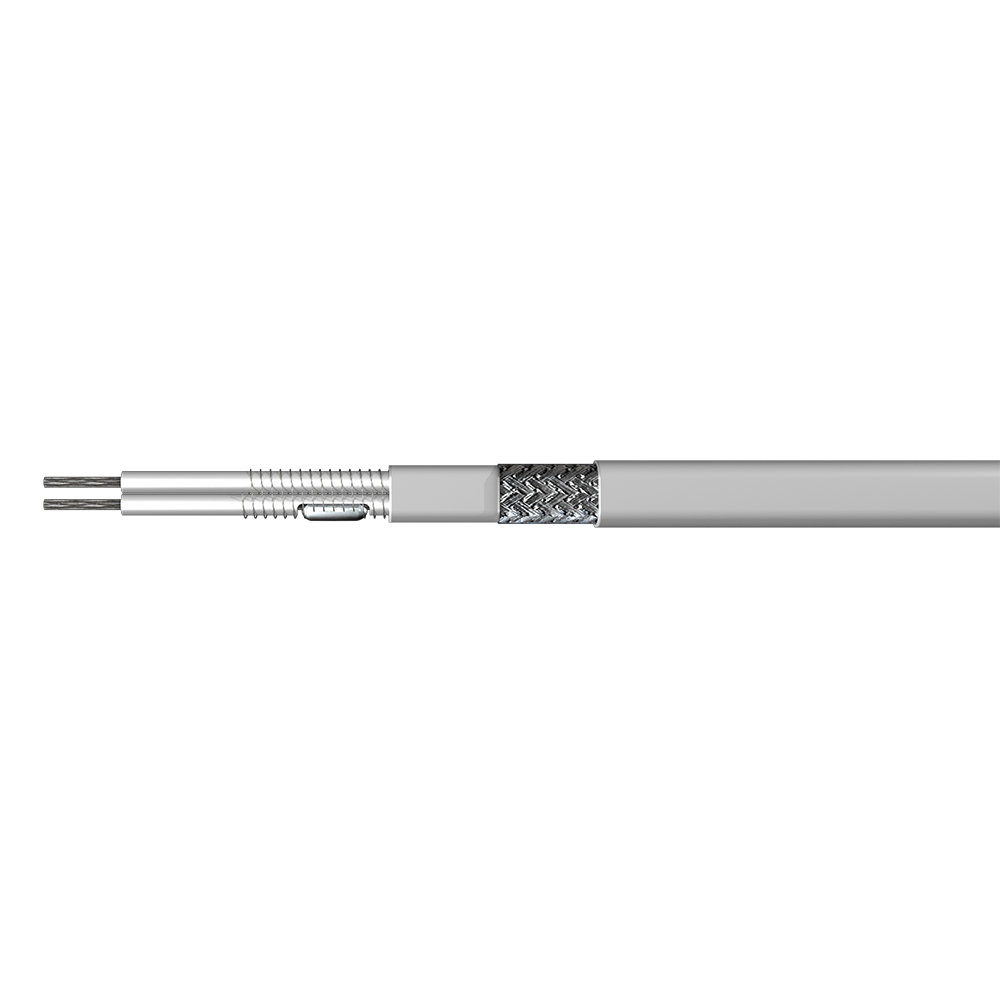

Constant Wattage Trace Heater is a flexible and efficient solution for process heating and flow control of viscous materials like wax and honey, as well as for use in corrosive environments with temperatures up to 797°F (425°C). Its heating value per unit length remains constant, allowing the output power to increase with the length of the belt. The heater can be cut to size on-site and installed close to pipelines for heat transfer. The outer braided layer enhances durability, aids in heat dissipation, and serves as a safety grounding wire.

Three-phase variants offer additional advantages: they support lengths three times longer than single-phase heaters with the same power rating and feature a larger cross-section for improved heat transfer efficiency. This makes the heater ideal for maintaining temperature, preventing freezing, or reducing viscosity in pipelines, tanks, and industrial equipment, ensuring reliable performance in demanding applications.

English

English русский

русский Français

Français Español

Español عربى

عربى