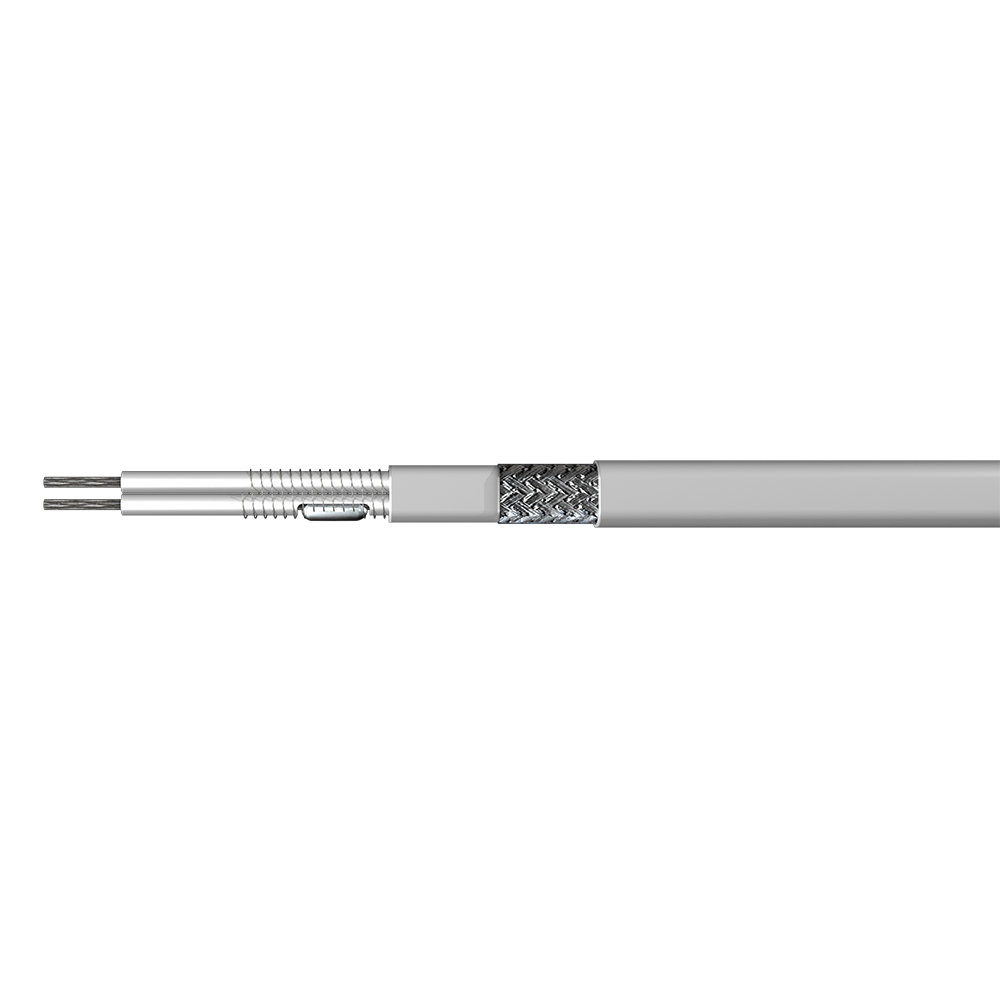

EJMI Heating Cable is a specialized heating solution designed with a robust construction, featuring ...

Heating Cables Manufacturers

-

-

Trace Heater Installation Kits and Accessories

Trace Heater Installation Kits and AccessoriesTrace Heater Installation Kits provide a complete range of components and accessories for efficient,...

-

Heating Trace Control Cabinet for Hazardous Location

Heating Trace Control Cabinet for Hazardous LocationHeating Trace Control Cabinet is a versatile solution for controlling and monitoring electrical heat...

-

Flexible Constant Power Heating Cable

Flexible Constant Power Heating CableConstant Wattage Heat Trace Cable is a reliable solution for process heating and temperature mainten...

-

Freeze Protection High Temperature Trace Heater

Freeze Protection High Temperature Trace HeaterHigh-Temperature Trace Heater is a specialized solution designed to apply controlled electric surfac...

-

Temperature Maintenance Low Temperature Trace Heater

Temperature Maintenance Low Temperature Trace HeaterLow Temperature Trace Heater is designed to provide controlled electric surface heating for pipework...

-

Middle Temperature Trace Heater for Underfloor Heating

Middle Temperature Trace Heater for Underfloor HeatingMiddle-Temperature Trace Heater is a reliable solution for applying controlled electric surface heat...

-

Constant Wattage Three-phase Trace Heater

Constant Wattage Three-phase Trace HeaterConstant Wattage Trace Heater is a flexible and efficient solution for process heating and flow cont...

Heat trace systems, also known as heating cables or trace heaters, are used to maintain or raise the temperature of pipes, tanks, and equipment to prevent freezing, maintain viscosity, or provide process heating. They come in various types, each suited for different applications based on environmental conditions, temperature requirements, and specific needs.

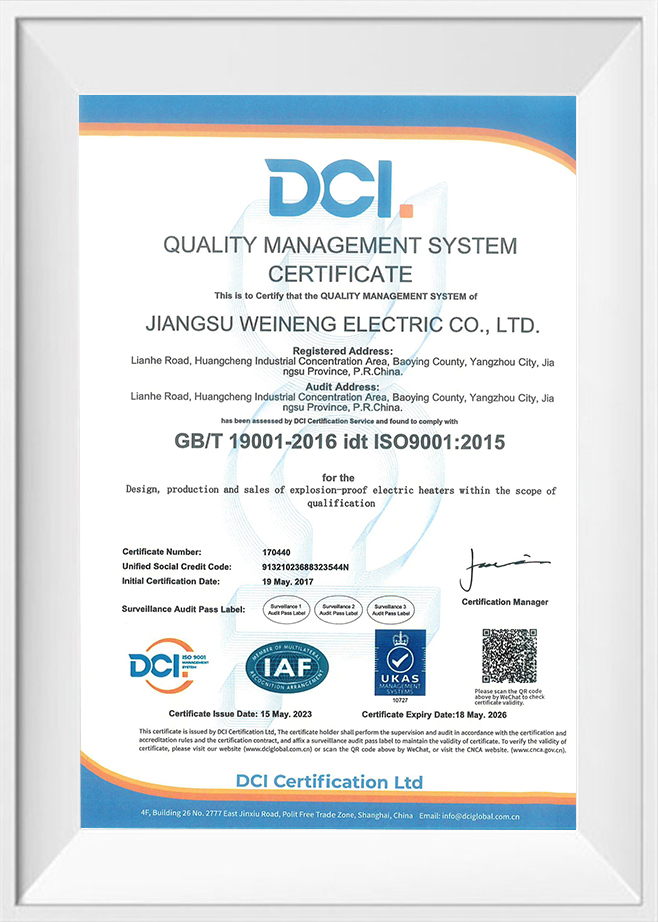

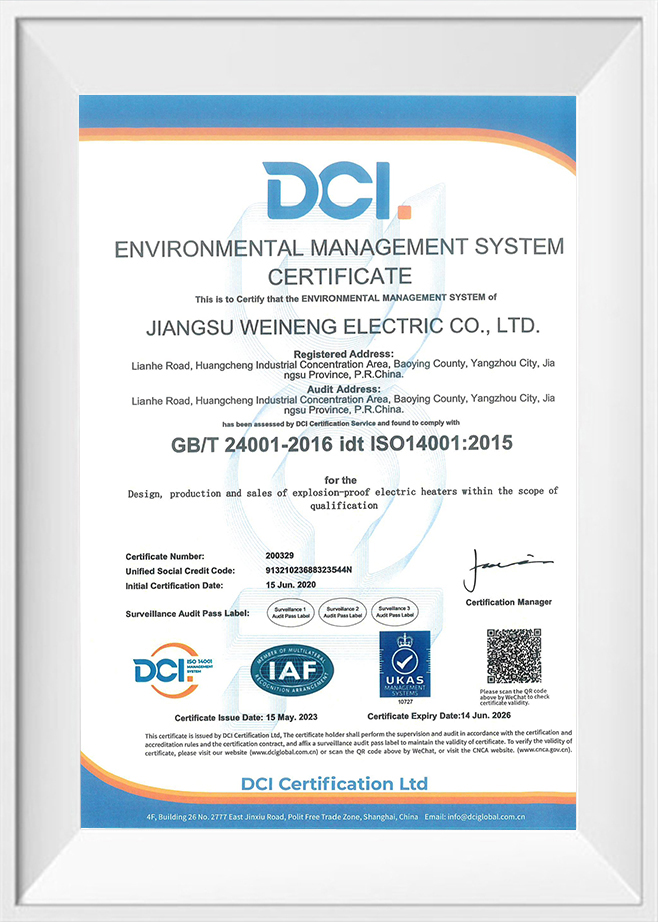

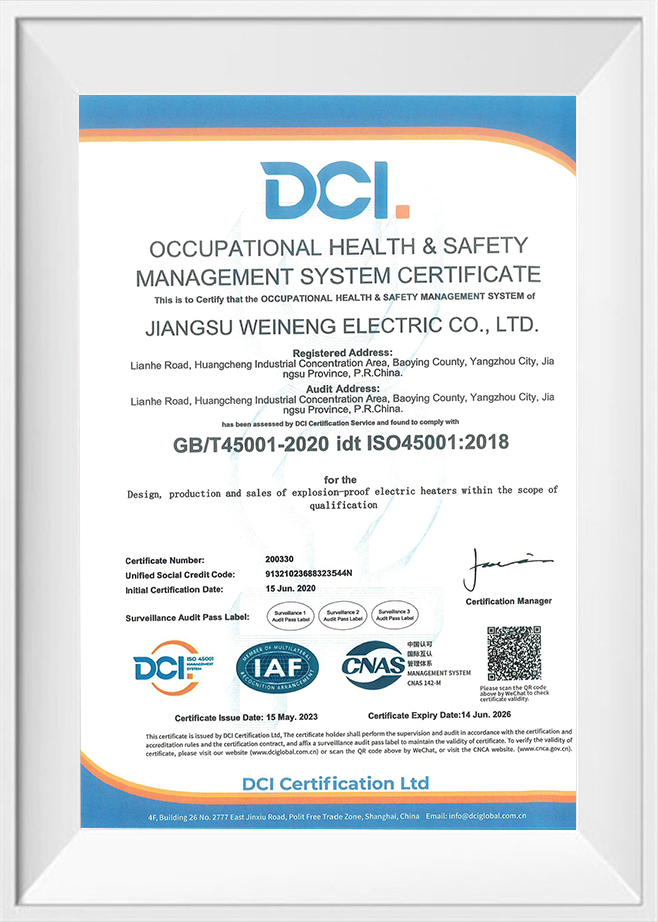

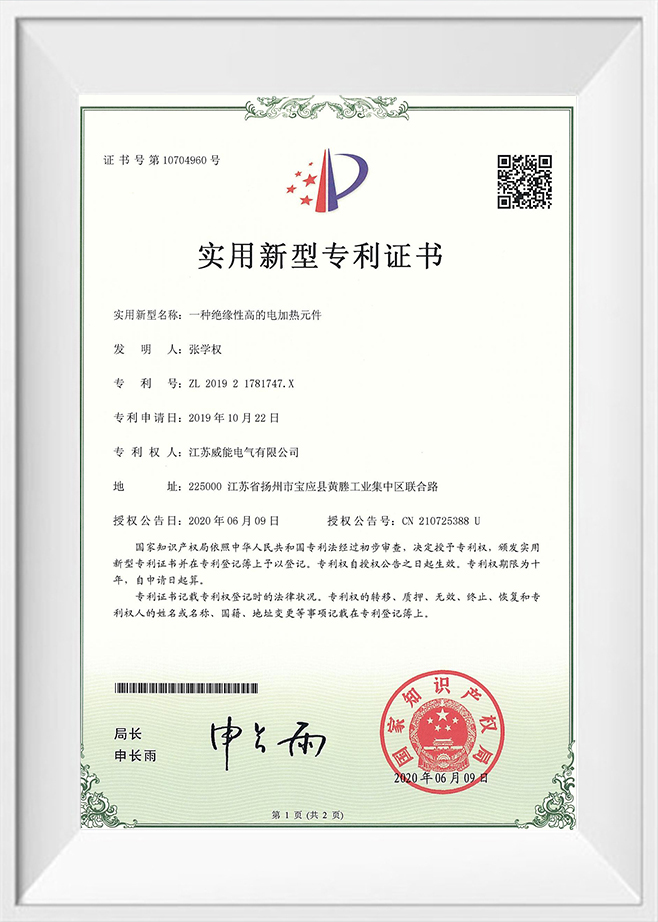

Jiangsu Weineng Electric Co.,Ltd established in April 23rd,2009, is a professional manufacturer engaged in the research, development, production, sale and service of Electric Heaters,Electric Heat Tracing Cable and Control system for industry.

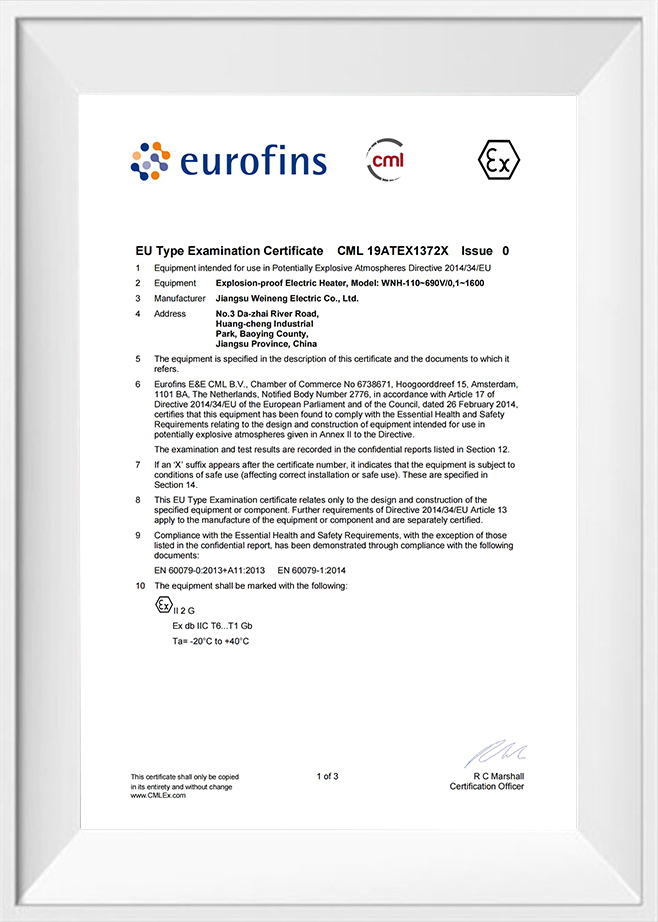

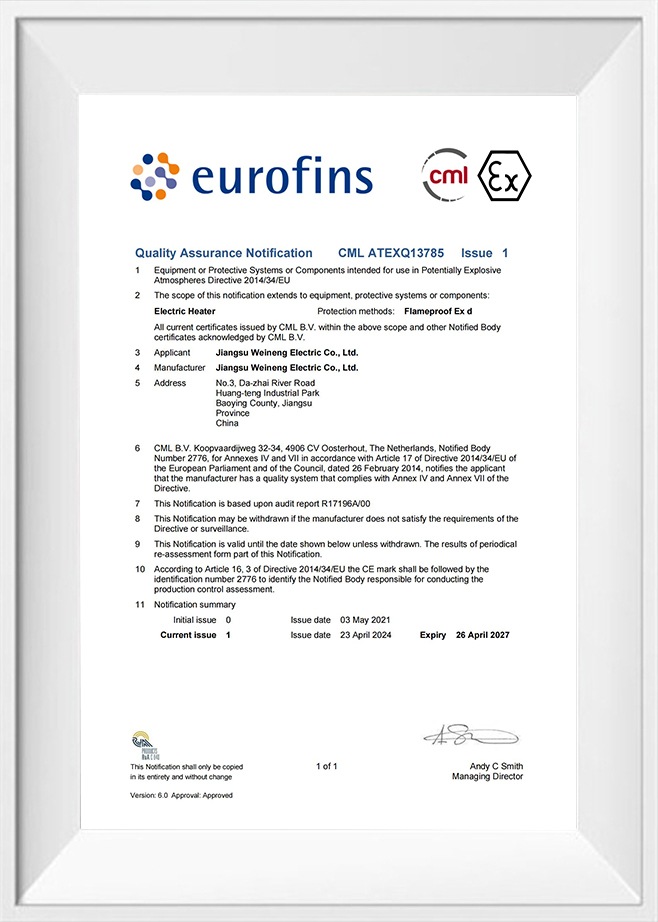

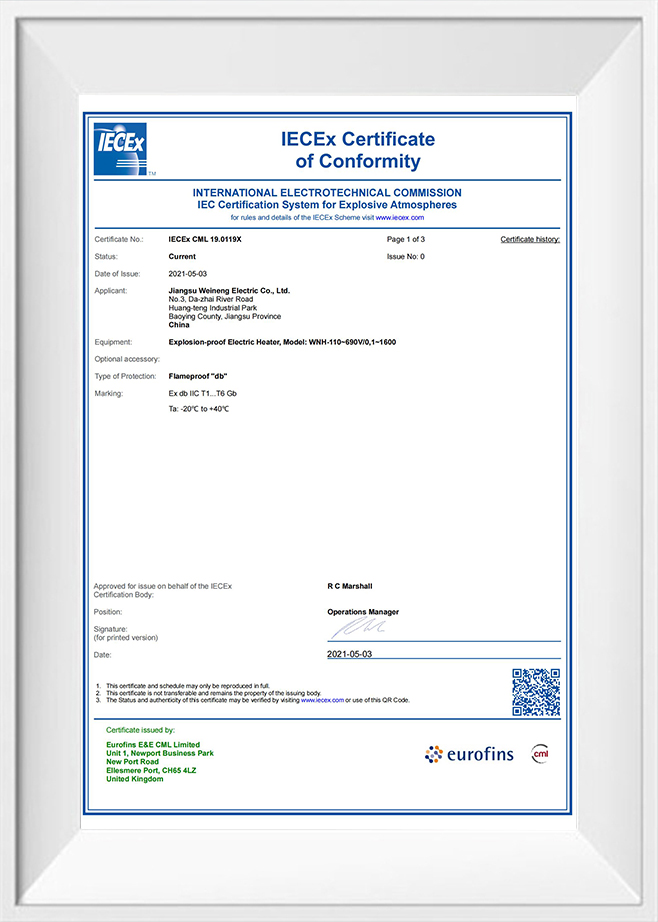

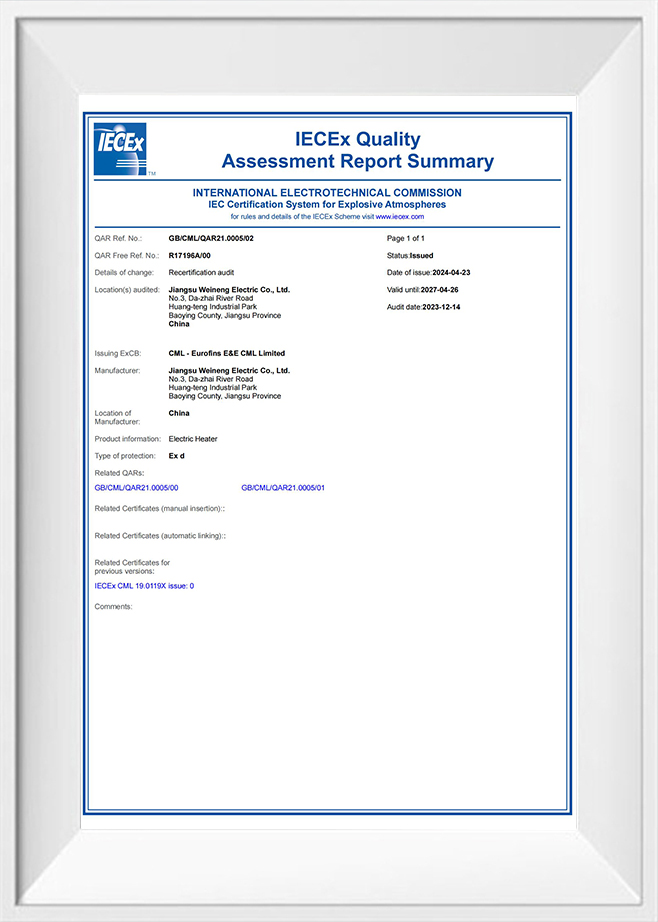

As China Trace Heater Manufacturers and Trace Heaters Factory, We are located in Baoying County,Jiangsu Province with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including power filling machine,electric pressure test pump,gauge lathe,LCD spot welding machine,drying cabinet,cleaning machine,dry sand blasting machine,automatic pipebender,digital multimeter,insulation resistance meter,voltage-resistant tester. Our company insist in technological innovation,we have 3 professors of engineering and dozens of young engineers with rich experience to orgonized a professional engineering team.We cooperate with universities and academies to research and develop new product. In addition, we have obtained IEcEx,Attex,ISO certificates.Selling well in all cities and provinces around China, We offer Wholesale Heat Trace Systems. our products are also exported to clients in such countries and regions as Middle East,Southeast Asia ,America and Europe. We also welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.Learn about our industry exhibition information and recent events in our company.

-

Explosion Proof Electrical Connectors: Selection & Safety Guide

What Explosion Proof Electrical Connectors Actually Do Explosion proof electrical connectors are not designed to prevent an internal spark or arc — t...25 -

Air Duct Heaters: Efficient HVAC Heating Solutions

Air Duct Heaters Deliver Targeted, Energy-Efficient Heating Directly Within HVAC Systems Air duct heaters are electric heating elements installed ins...19 -

Air Duct Heaters for Efficient HVAC Temperature Control

Air Duct Heaters as a Practical Heating Solution Air duct heaters are an efficient and controllable way to raise or stabilize air temperature directl...09 -

Electric Immersion Heater: Types, Uses & Safety Tips

Electric Immersion Heater: Quick Overview and Conclusion Electric immersion heaters are highly efficient devices for heating liquids directly in tank...05 -

Can Upgrading Process Heaters Boost Manufacturing Competitiveness?

The Role of Process Heaters in Modern Manufacturing Process heaters are critical components in industrial operations, providing the controlled heat ne...30

How to Design an Efficient Heat Trace System: Key Parameters, Calculations, and Common Pitfalls

Designing an efficient and reliable heat trace system starts well before a single meter of cable is installed. Whether you're protecting pipelines from freezing or ensuring stable process temperatures, the design phase determines not only operational effectiveness but also long-term energy efficiency and maintenance costs. It's tempting to think of heat trace systems as plug-and-play solutions, but in practice, each system must be tailored to specific site conditions and technical demands. Misjudging a single parameter—like ambient temperature or insulation thickness—can lead to undersized heating or, worse, system failure.

The first step in design is a clear understanding of the heat loss from the pipe or tank to the surrounding environment. This heat loss must be precisely calculated using factors like pipe size, length, insulation type, ambient low temperatures, and wind exposure. Based on that, the required power output of the heating cables can be determined. Many manufacturers provide heat loss tables, but custom calculations using thermal formulas are often necessary for critical applications or non-standard installations. Selecting the correct output rating (e.g., watts per meter) is a fine balance—too low, and the system underperforms; too high, and you risk overheating or unnecessary energy waste.

Once you know the heat loss, choosing the appropriate type of heating cable becomes the next priority. Self-regulating trace heaters are a common choice for freeze protection and moderate-temperature maintenance because of their ability to adjust output with temperature changes. In contrast, constant wattage cables provide uniform heat and are more suitable for process heating where stable power delivery is critical. For high-temperature applications or hazardous environments, mineral insulated cables offer unmatched durability but require more careful planning in terms of termination and bend radius.

Control strategy is another essential design factor that is often underestimated. A basic thermostat may suffice for small, non-critical systems, but larger or process-sensitive installations benefit greatly from advanced control panels, sensor feedback, and even smart, IoT-enabled monitoring. These options not only enhance precision but also reduce operational costs by optimizing cable performance in real-time. Control systems are often overlooked during procurement, but they’re where much of the system’s efficiency can be gained—or lost.

A common pitfall in heat trace system design is underestimating the role of proper insulation. Even the most advanced heating cable can’t compensate for poorly installed or degraded insulation. It's also critical to account for pipe supports, valves, and flanges in the design, as these components can act as thermal bridges, requiring extra heating attention. These small design oversights often result in cold spots or require costly redesigns down the line, particularly in process facilities where thermal consistency is crucial.

Beyond the physical and thermal calculations, environmental and regulatory conditions also play a role. For example, heating cables installed in outdoor or hazardous environments must comply with specific certification standards like ATEX or IECEx. Additionally, moisture ingress protection, UV resistance, and chemical compatibility should be carefully evaluated based on the surrounding environment. This level of diligence not only ensures safety but also improves system longevity—something any experienced manufacturer will stress during the planning stages.

As a manufacturer deeply involved in industrial and commercial heat trace systems, we’ve seen firsthand how proper planning sets the foundation for long-term performance. From selecting the right trace heaters to configuring smart control systems, every detail matters. When done correctly, a well-designed system not only meets technical requirements but adds real value to your operation.

English

English русский

русский Français

Français Español

Español عربى

عربى