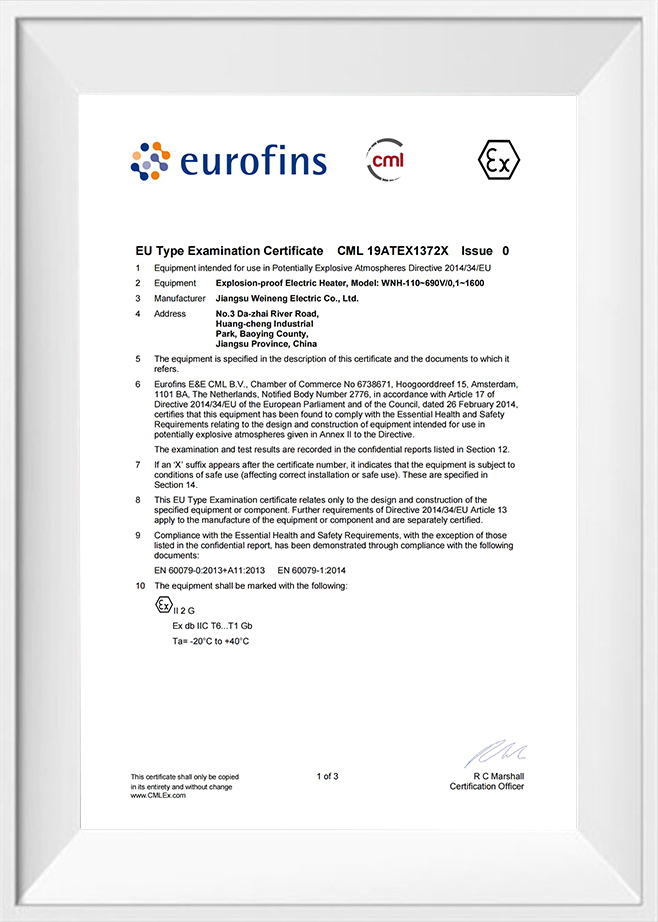

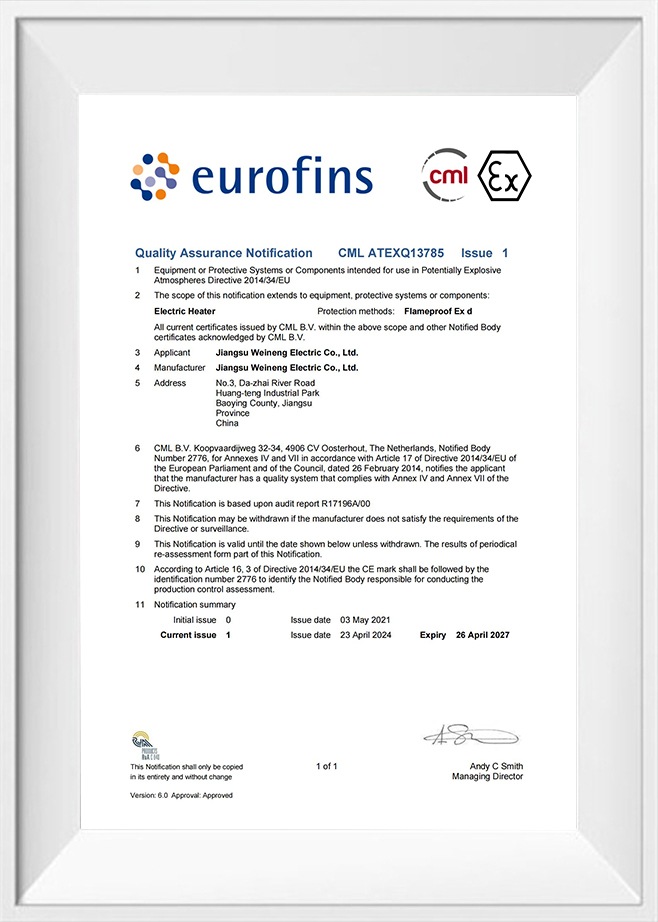

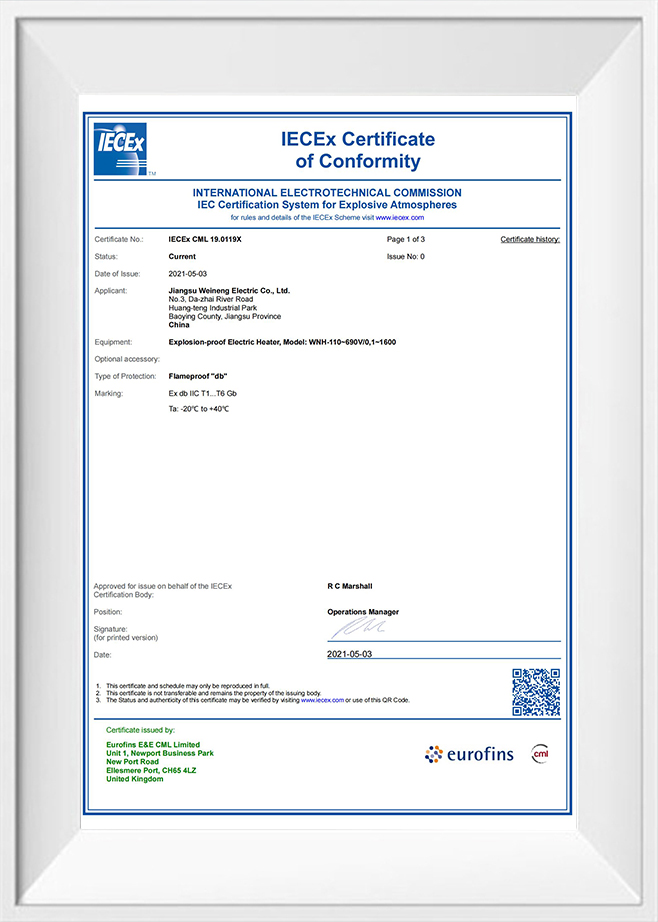

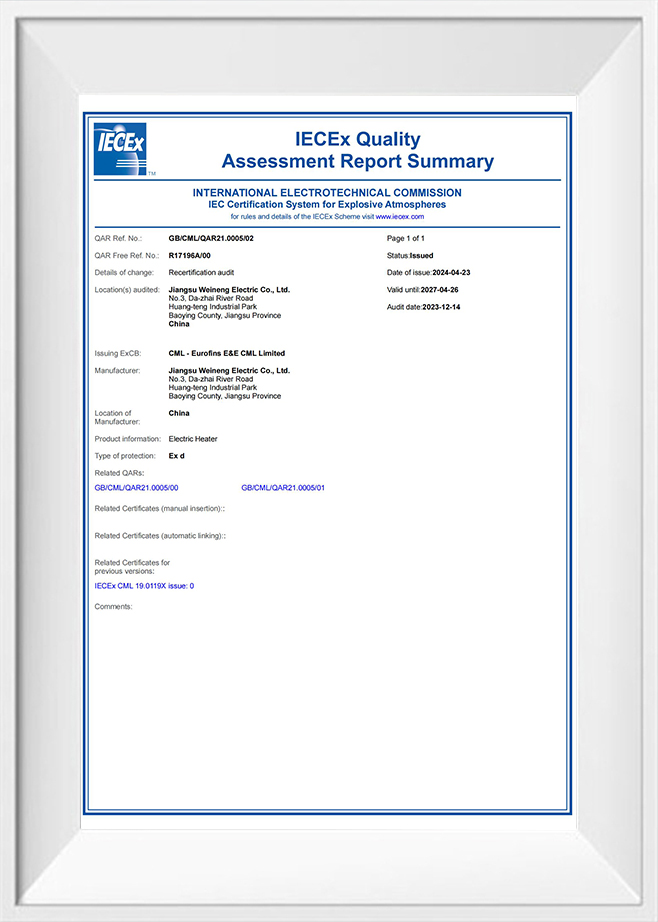

The Process Area Immersion Heater for Large Machines by WNH is a high-performance immersion heater specifically designed for large industrial machinery. With a maximum power output ranging from 2000KW to 3000KW and a maximum operating voltage of 690VAC, this heater is engineered to meet the demanding needs of industrial applications. It is ATEX and IECEx certified with Exd, Exe, IIC Gb, T1-T6 explosion protection, making it suitable for Zone 1 and Zone 2 hazardous areas, ensuring safe operation in high-risk environments.

This heater is built with high-quality anti-corrosion and high-temperature resistant heating element materials, including Inconel 600, Incoloy 800/825/840, Hastelloy, titanium alloys, and stainless steel grades such as 304, 321, 310S, and 316L. These materials ensure the longevity and stability of the equipment even in conditions. The heating element uses NiCr 80/20 wire, with either single or double coil designs to optimize heating efficiency and performance.

The product is designed according to ASME code and other international standards, equipped with over-temperature protection devices (such as PT100, thermocouples, or thermostats), ensuring automatic shutdown in case of overheating to prevent malfunctions. The heating element is connected to the flange via Bite-Coupling or direct welding. The Bite-Coupling design allows for offline replacement of individual elements, simplifying maintenance and replacement processes.

English

English русский

русский Français

Français Español

Español عربى

عربى