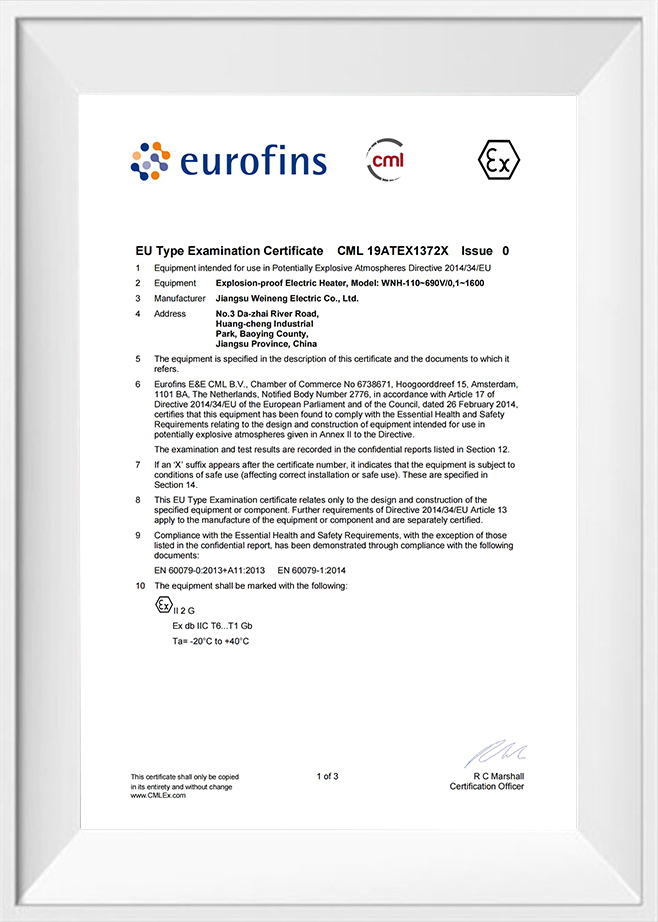

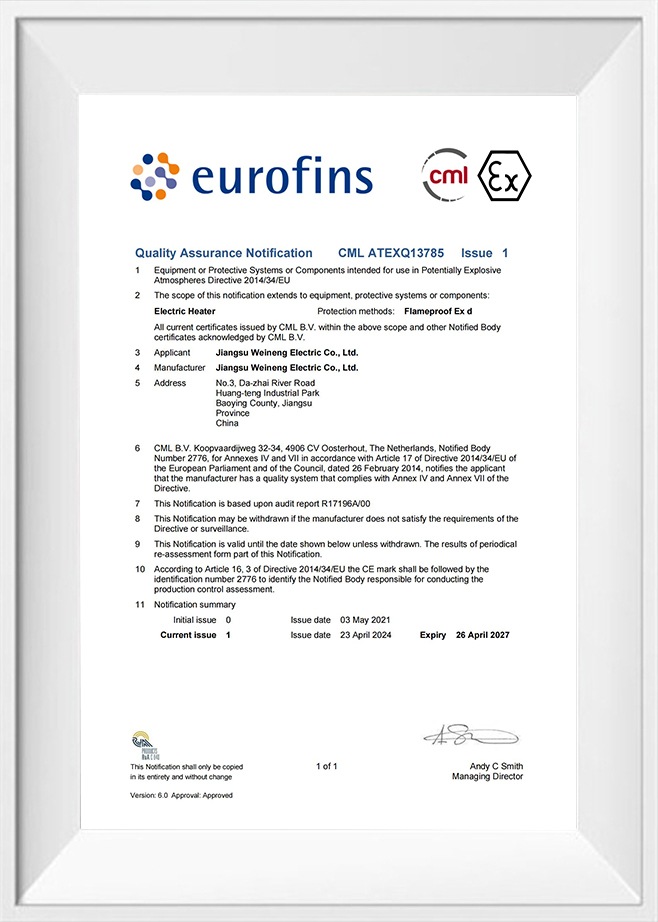

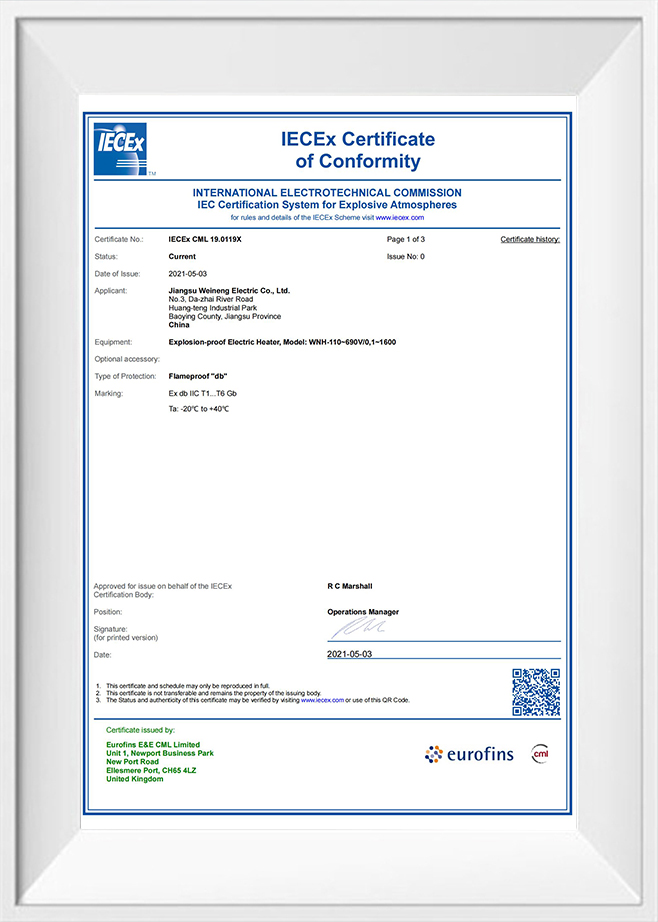

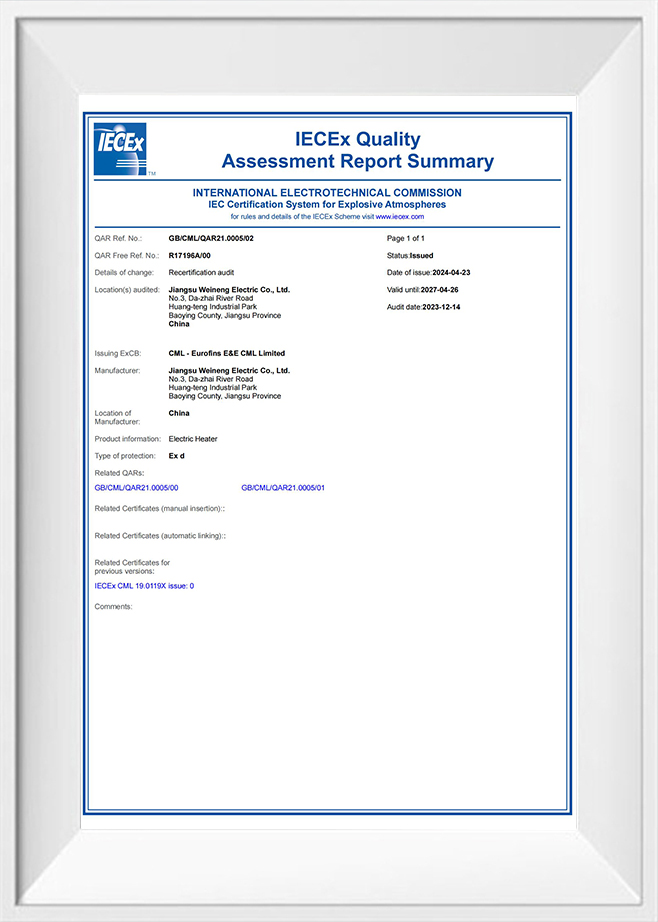

Compressor Hazardous Area Immersion Heater is a high-performance heating solution designed for demanding applications in hazardous environments. With a power capacity of up to 2000KW–3000KW and a maximum voltage of 690VAC, it ensures efficient and reliable heating. Certified with ATEX and IECEx approvals (Exd, Exe, IIC Gb, T1-T6), it is suitable for Zone 1 and Zone 2 applications, guaranteeing safety in explosive atmospheres.

Constructed from premium materials like Inconel 600, Incoloy 800/825/840, Hastelloy, Titanium, and stainless steel (304, 321, 310S, 316L), the heater offers exceptional resistance to corrosion and high temperatures. Its NiCr 80/20 heating wires, available in single or double coils, ensure consistent heat transfer and durability. Designed to ASME and international standards, it combines quality and reliability.

The hair-pin elements are sealed to the tube sheet via Bite-Coupling or Direct Welding, allowing offline replacement when using Bite-Coupling. Over-temperature protection is provided by PT100 sensors, thermocouples, or thermostats integrated into the heating element, flange, and terminal box. The IP66 ingress protection rating ensures resilience in harsh conditions, while the flanged design simplifies installation and maintenance.

Applications include heating lubricating oils for compressors, turbines, and pumps, as well as process heaters for heat transfer oils, heavy oils, fuels, and gases. It is also ideal for container heating, emergency showers, and anti-condensation systems. Built for cyclic or continuous operation, this explosion-proof heater delivers precision, durability, and safety, making it a trusted choice for hazardous-area heating needs.

English

English русский

русский Français

Français Español

Español عربى

عربى