380V 60KW EX Process Heater is a versatile and efficient solution for industrial heating application...

Process Immersion Heaters Manufacturers

-

-

380V 270KW EX Process Heater

380V 270KW EX Process Heater380V 270KW EX Process Heater is a high-performance explosion-proof electric heater designed to conve...

-

380V 300KW Industrial Electric Process Heater

380V 300KW Industrial Electric Process Heater380V 300KW Industrial Electric Heater is a robust and efficient solution designed to convert electri...

-

380V 1600KW Ex-Proof Industrial Electric Process Heater

380V 1600KW Ex-Proof Industrial Electric Process Heater380V 1600KW Ex-Proof Industrial Electric Heater is a high-efficiency, customizable heating solution ...

-

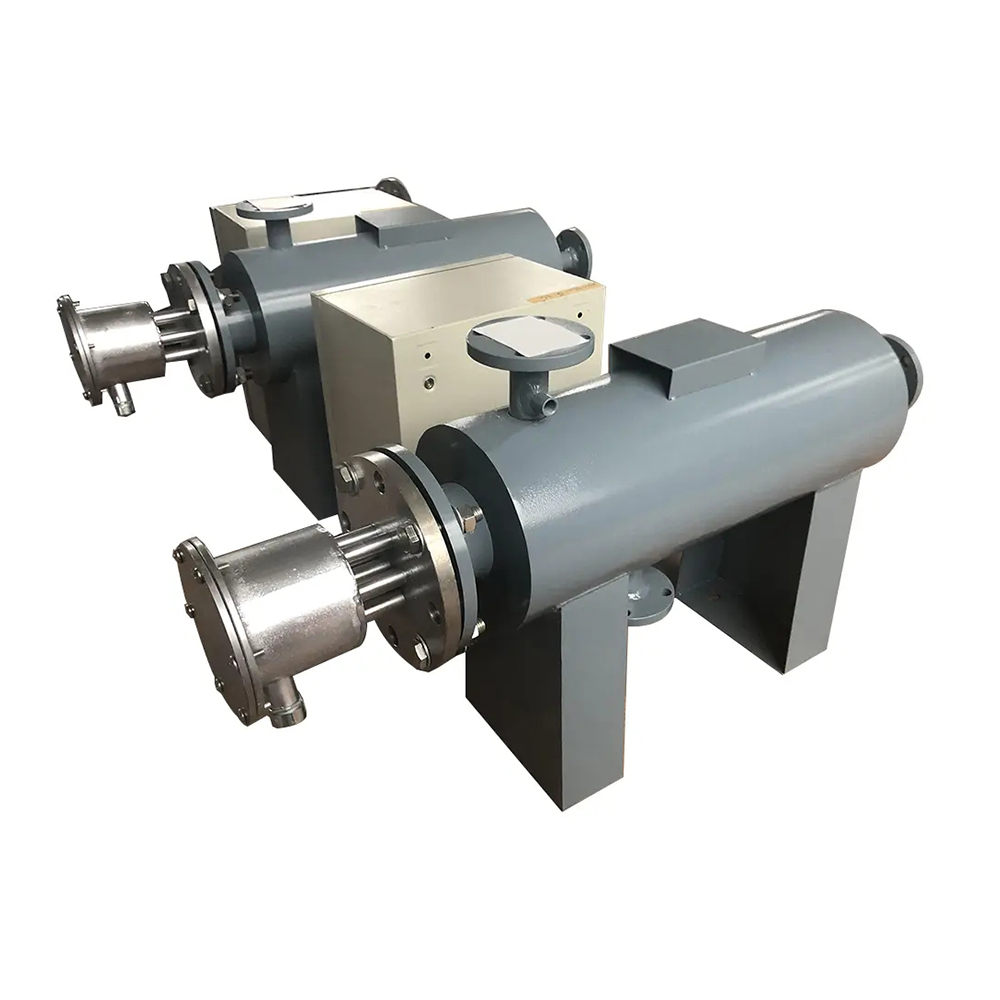

Compressed Air Electric Process Heater

Compressed Air Electric Process HeaterThe Compressed Air Electric Heater is a compact, high-efficiency heating solution with a working tem...

-

Indirect Line Electric Gas Process Heater

Indirect Line Electric Gas Process HeaterThe Indirect Line Electric Gas Process Heater is a specialized heating solution designed to countera...

-

Industrial Nitrogen Process Heater

Industrial Nitrogen Process HeaterNitrogen Process Heater is a specialized solution designed to address the unique challenges of heati...

-

RTO Desulfurization and Denitrification Process Heater

RTO Desulfurization and Denitrification Process HeaterRTO Desulfurization and Denitrification Process Heater is a specialized solution designed to support...

Process heaters are advanced industrial heating systems designed to transfer heat directly to process fluids, gases, or materials in a controlled and efficient manner. These heaters are essential in industries such as oil and gas, chemical processing, power generation, and food manufacturing, where precise temperature control and reliability are critical.

Constructed from high-quality materials like stainless steel, Incoloy, or specialized alloys, process heaters are engineered to handle temperatures, high pressures, and corrosive environments. They come in various configurations, including circulation heaters, inline heaters, and immersion heaters, to meet specific process requirements.

Modern process heaters are equipped with features such as advanced temperature controls, integrated safety mechanisms, and energy-efficient designs to optimize performance and minimize operational costs. Whether for heating crude oil, steam, or chemical solutions, process heaters deliver dependable and customizable solutions tailored to industrial needs.

Jiangsu Weineng Electric Co.,Ltd established in April 23rd,2009, is a professional manufacturer engaged in the research, development, production, sale and service of Electric Heaters,Electric Heat Tracing Cable and Control system for industry.

As China LNG Electric Heaters Manufacturers and LNG Electric Heater Factory, We are located in Baoying County,Jiangsu Province with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including power filling machine,electric pressure test pump,gauge lathe,LCD spot welding machine,drying cabinet,cleaning machine,dry sand blasting machine,automatic pipebender,digital multimeter,insulation resistance meter,voltage-resistant tester. Our company insist in technological innovation,we have 3 professors of engineering and dozens of young engineers with rich experience to orgonized a professional engineering team.We cooperate with universities and academies to research and develop new product. In addition, we have obtained IEcEx,Attex,ISO certificates.Selling well in all cities and provinces around China, We offer Custom Industrial Flue Gas Heater. our products are also exported to clients in such countries and regions as Middle East,Southeast Asia ,America and Europe. We also welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.Learn about our industry exhibition information and recent events in our company.

-

Explosion Proof Electrical Connectors: Selection & Safety Guide

What Explosion Proof Electrical Connectors Actually Do Explosion proof electrical connectors are not designed to prevent an internal spark or arc — t...25 -

Air Duct Heaters: Efficient HVAC Heating Solutions

Air Duct Heaters Deliver Targeted, Energy-Efficient Heating Directly Within HVAC Systems Air duct heaters are electric heating elements installed ins...19 -

Air Duct Heaters for Efficient HVAC Temperature Control

Air Duct Heaters as a Practical Heating Solution Air duct heaters are an efficient and controllable way to raise or stabilize air temperature directl...09 -

Electric Immersion Heater: Types, Uses & Safety Tips

Electric Immersion Heater: Quick Overview and Conclusion Electric immersion heaters are highly efficient devices for heating liquids directly in tank...05 -

Can Upgrading Process Heaters Boost Manufacturing Competitiveness?

The Role of Process Heaters in Modern Manufacturing Process heaters are critical components in industrial operations, providing the controlled heat ne...30

Applications of Process Immersion Heaters in Oil, Gas, and Chemical Industries

Process immersion heaters play a crucial role in maintaining operational efficiency and safety across a wide range of industrial sectors, particularly in oil, gas, and chemical processing. These heaters are designed to deliver consistent and controlled heat directly into process fluids such as crude oil, chemical solutions, and liquefied gases. Their robust design, high thermal efficiency, and adaptability make them a foundational component in environments where temperature regulation is critical to production and safety.

What Is a Process Immersion Heater?

A process immersion heater is an electric heating element that is directly immersed into liquids, gases, or viscous fluids to transfer thermal energy efficiently. These heaters are often integrated into tanks, pipelines, or other containment systems. Designed to withstand harsh industrial conditions, they are built using corrosion-resistant materials like stainless steel, Incoloy, or other high-performance alloys that provide durability in extreme pressure and temperature environments.

In industries such as petroleum refining, chemical production, and natural gas processing, immersion heaters ensure that process materials remain at precise temperatures, preventing freezing, crystallization, or degradation during production. Whether used to maintain flowability of heavy oils or to heat LNG (Liquefied Natural Gas) for downstream applications, process immersion heaters help operators maintain a reliable, continuous process.

Applications in the Oil Industry

In the oil industry, the ability to maintain optimal fluid temperature is essential for both efficiency and safety. Process immersion heaters are frequently used to heat crude oil and other petroleum products to reduce viscosity and facilitate easier transportation through pipelines. This is particularly important in colder environments where the natural flow of oil can be impeded.

Additionally, immersion heaters are used in degassing systems, separation processes, and tank heating applications. For offshore and onshore operations, LNG electric heaters and industrial flue gas heaters are also deployed to ensure the heating of gases and liquids under controlled parameters, enabling operators to meet strict operational and environmental standards.

Role in the Gas and LNG Sectors

Natural gas processing, especially in the case of liquefied natural gas (LNG), demands precise temperature control. Liquefied natural gas heaters are specialized types of process heaters designed to safely vaporize or heat LNG as it transitions from its cryogenic state to a usable gaseous form. LNG electric heaters offer a safe and efficient method to handle this transformation, reducing the reliance on combustion-based heating methods and aligning with sustainability goals.

These heaters are particularly beneficial for re-gasification terminals, LNG storage facilities, and transportation systems. Their ability to deliver consistent heat without open flames makes them ideal for hazardous areas, meeting the safety regulations common in these sectors. In such installations, process immersion heaters are often integrated with safety mechanisms and control systems to monitor temperature, flow, and pressure in real time.

Importance in Chemical Processing

In chemical manufacturing, temperature control directly affects product quality and process efficiency. A wide range of chemical reactions require exact thermal conditions to proceed safely and effectively. Process immersion heaters are used to maintain these conditions in mixing tanks, reactors, and pipelines, especially where corrosive or volatile substances are involved.

Industrial flue gas heaters also play an important role in emission control systems, where they help maintain the required temperature for exhaust treatment or catalyst activation. Many chemical plants integrate electric heating systems like immersion or inline heaters to eliminate the risks associated with combustion-based methods, especially in confined or sensitive environments.

Jiangsu Weineng Electric Co., Ltd., founded on April 23, 2009, is a professional manufacturer committed to providing high-quality industrial heating solutions. Specializing in electric heaters, electric heat tracing cables, and control systems, the company serves a diverse customer base both domestically and internationally.

Located in Baoying County, Jiangsu Province, Jiangsu Weineng benefits from convenient transportation access and a fully equipped manufacturing facility. The company has invested in advanced production and testing equipment, including power filling machines, electric pressure test pumps, and digital multimeters. This infrastructure enables the company to manufacture reliable and durable products, including process immersion heaters, industrial flue gas heaters, LNG electric heaters, and liquefied natural gas heaters.

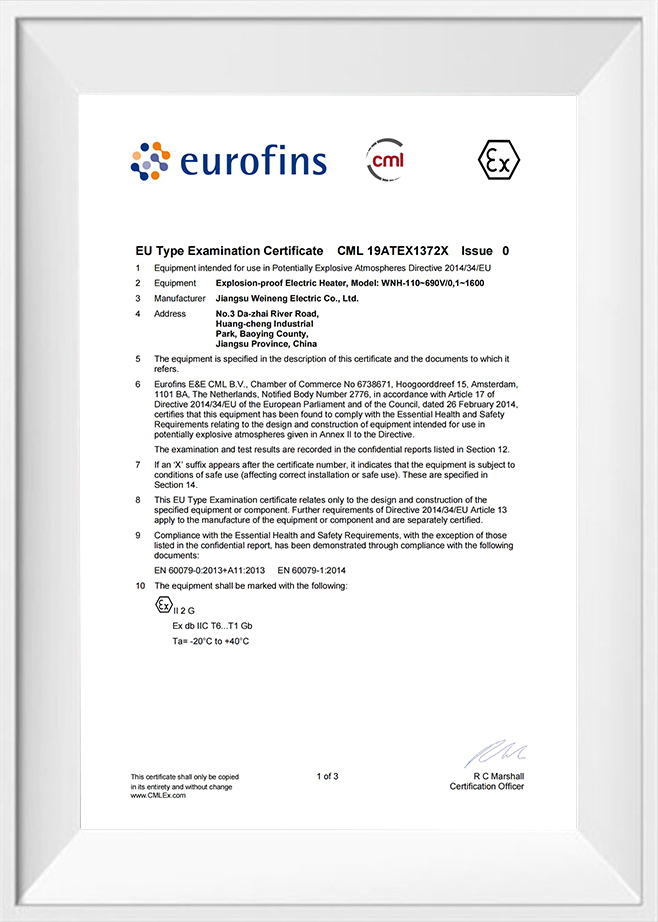

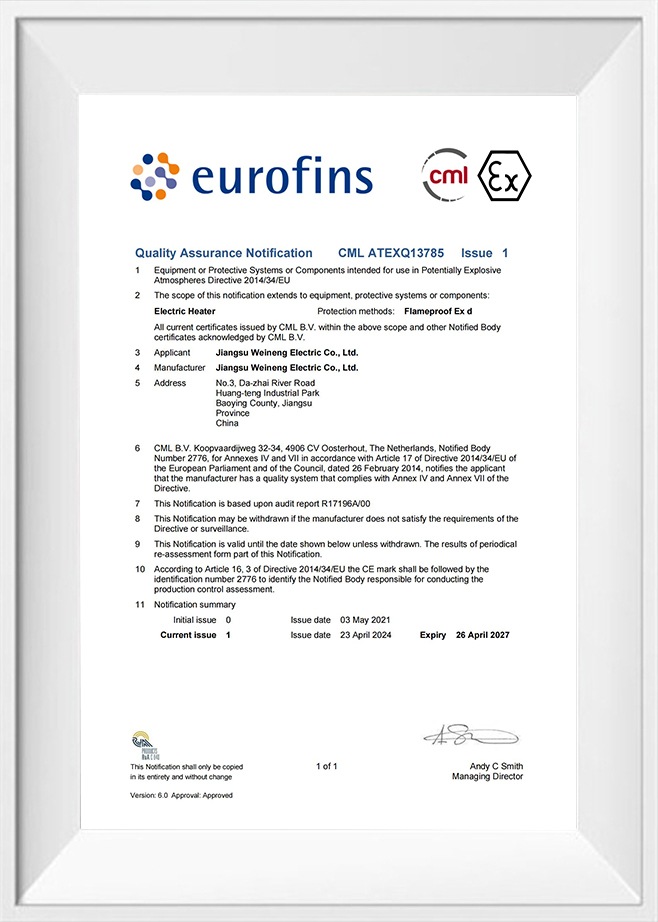

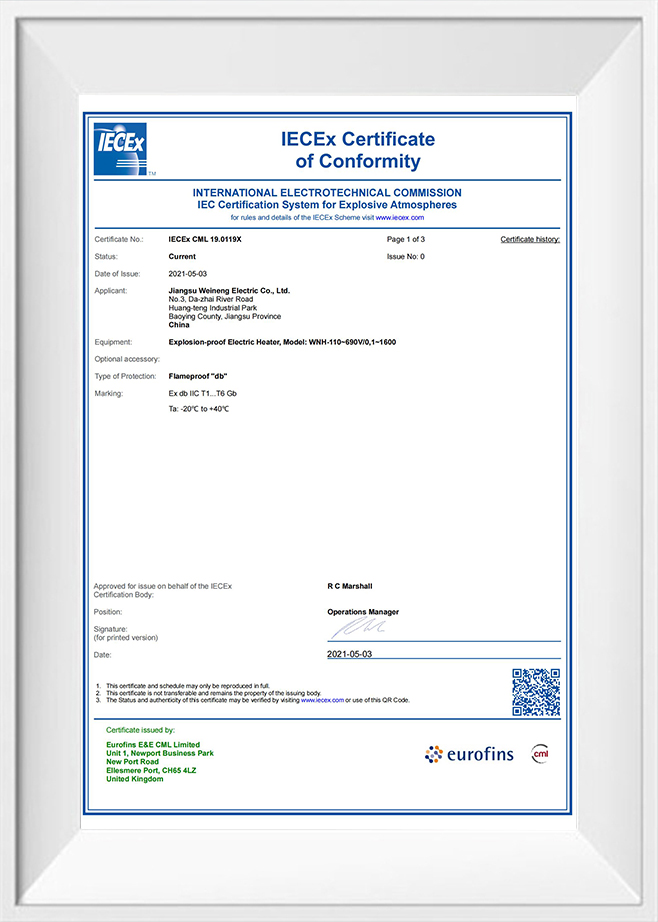

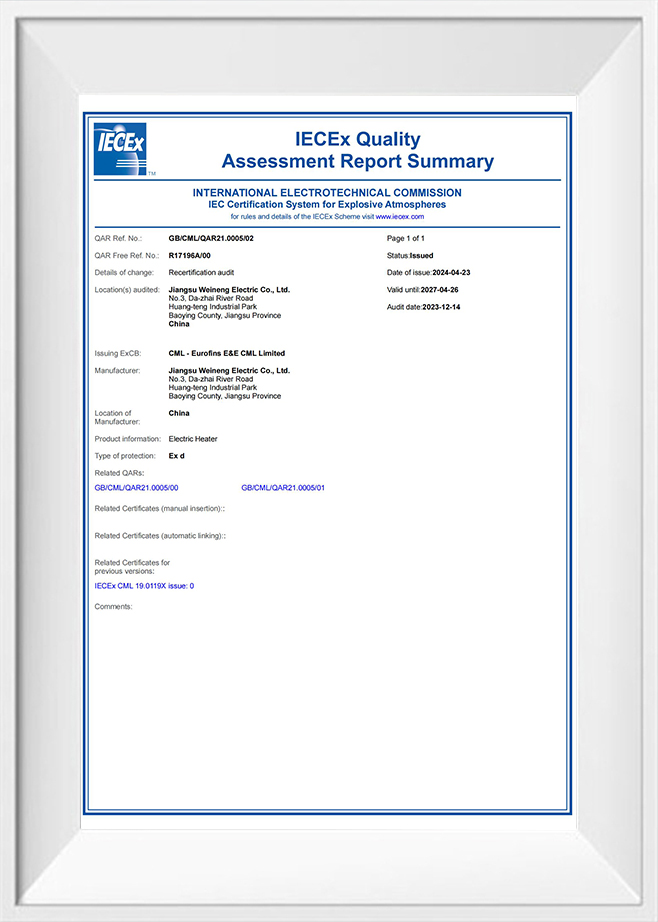

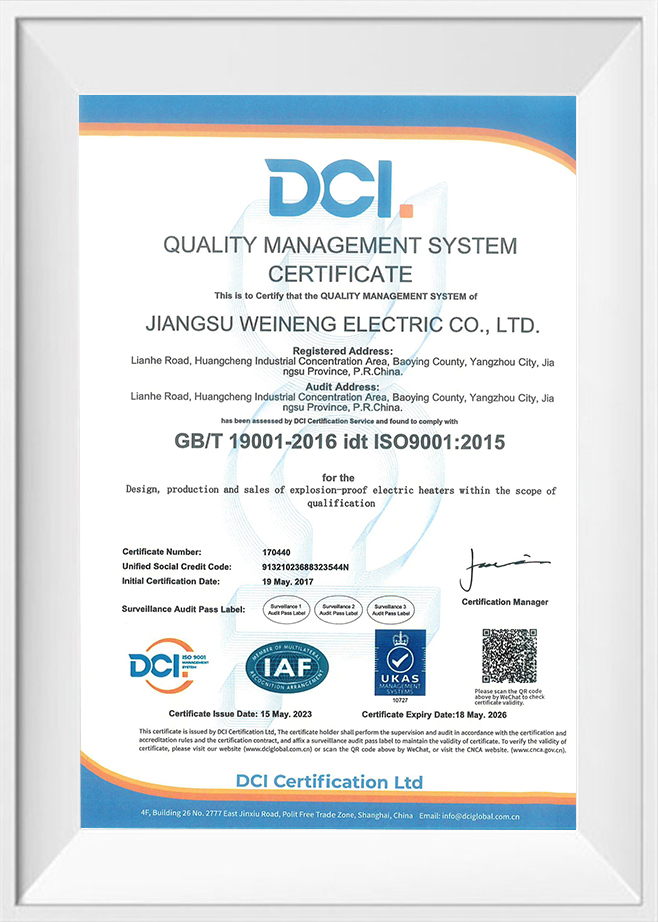

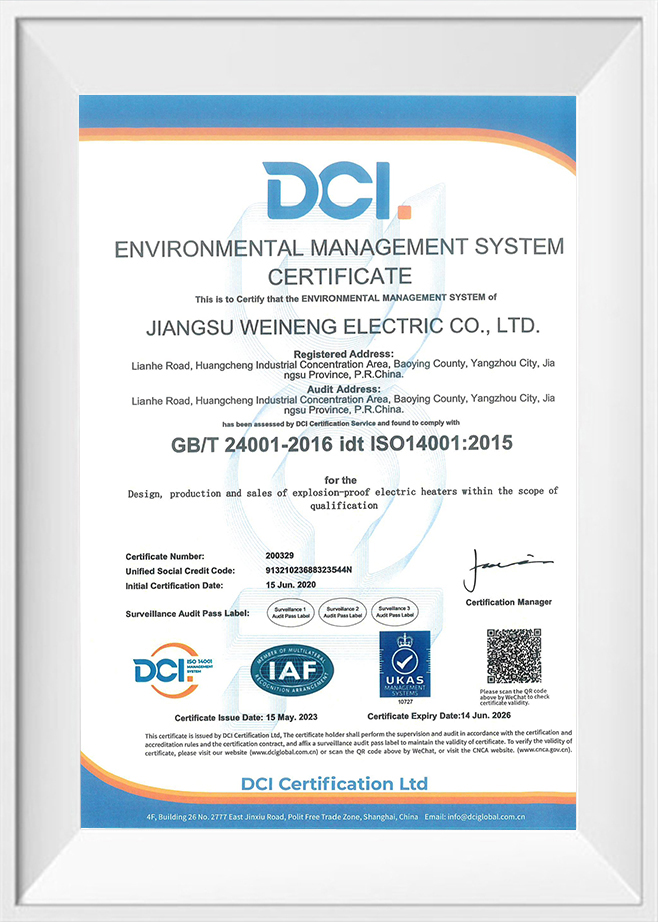

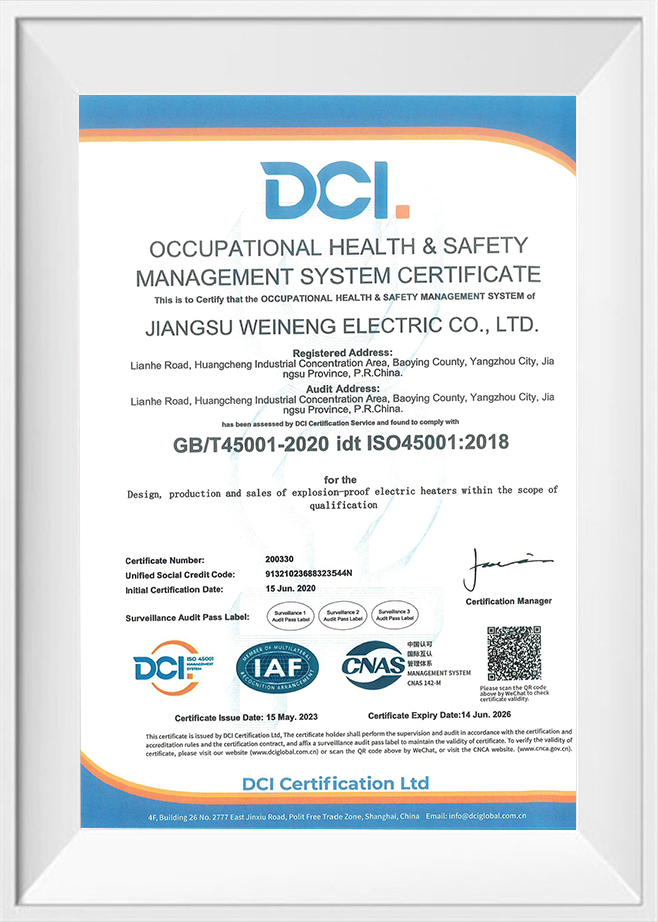

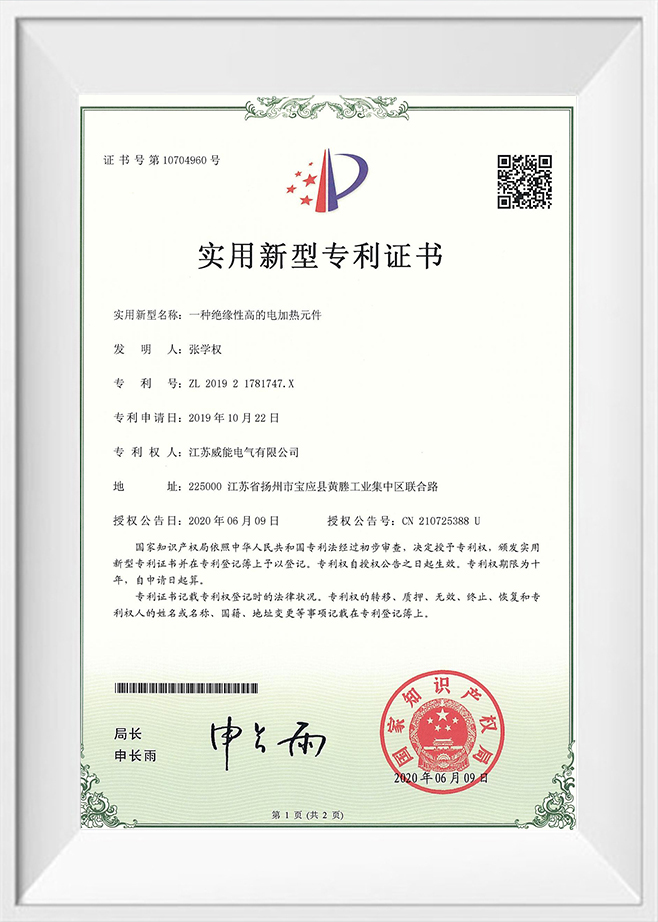

Jiangsu Weineng maintains a strong focus on technological innovation. Its engineering team comprises three senior engineering professors and dozens of experienced young engineers. The company collaborates closely with universities and research institutes to develop new technologies and improve product performance. With certifications including IECEx, ATEX, and ISO, the company adheres to international standards for quality and safety.

Today, Jiangsu Weineng’s products are sold across China and exported to markets in Southeast Asia, the Middle East, Europe, and the Americas. The company also offers OEM and ODM services, supporting clients with customized heating solutions tailored to specific industrial requirements. Whether heating chemical solutions in a reactor or vaporizing LNG in a terminal, Jiangsu Weineng’s heaters are built for performance, safety, and longevity.

Process immersion heaters, LNG electric heaters, liquefied natural gas heaters, and industrial flue gas heaters are essential tools in the oil, gas, and chemical industries. They ensure process continuity, product integrity, and operational safety. With rising demand for clean and efficient energy systems, the importance of these heaters is only growing.

By combining engineering expertise, high-quality materials, and advanced manufacturing techniques, companies like Jiangsu Weineng Electric Co., Ltd. are helping industries meet their heating needs in a safe, efficient, and reliable manner. Whether you need to maintain the temperature of crude oil, heat chemical solutions, or manage LNG transitions, process immersion heaters remain a vital part of modern industrial infrastructure.

English

English русский

русский Français

Français Español

Español عربى

عربى