Anti-Explosion Skid Heater is a compact, efficient heating solution designed for easy installation a...

Electric Skid Heaters Manufacturers

-

-

Industrial Electric Skid Heater

Industrial Electric Skid HeaterIndustrial Electric Skid Heater by WNH is a highly customizable and efficient heating solution desig...

-

Skid-Mounted Immersion Heater

Skid-Mounted Immersion HeaterSkid-Mounted Immersion Heater is a versatile and mobile heating solution designed to simplify the pr...

-

Offshore Skid Platform

Offshore Skid PlatformBuilt with materials and construction techniques, the Offshore Skid Platform is capable of withstand...

Packaged skid systems are fully integrated, pre-assembled solutions designed to streamline complex industrial processes by combining heating, pumping, control, and auxiliary equipment into a compact and modular unit. These systems are widely used in industries such as oil and gas, chemical processing, power generation, and water treatment for applications like fluid heating, thermal management, and chemical injection.

Built with precision engineering and high-quality materials, packaged skid systems are customized to meet specific operational requirements, including temperature, pressure, and flow rate specifications. They often include advanced features such as programmable logic controllers (PLCs), real-time monitoring, and safety interlocks, ensuring reliable performance and operational safety.

By minimizing on-site installation time and simplifying maintenance, packaged skid systems reduce project costs and enhance system efficiency. Their modular design allows for easy transportation, installation, and scalability, making them an ideal choice for industries requiring robust and flexible solutions.

Jiangsu Weineng Electric Co.,Ltd established in April 23rd,2009, is a professional manufacturer engaged in the research, development, production, sale and service of Electric Heaters,Electric Heat Tracing Cable and Control system for industry.

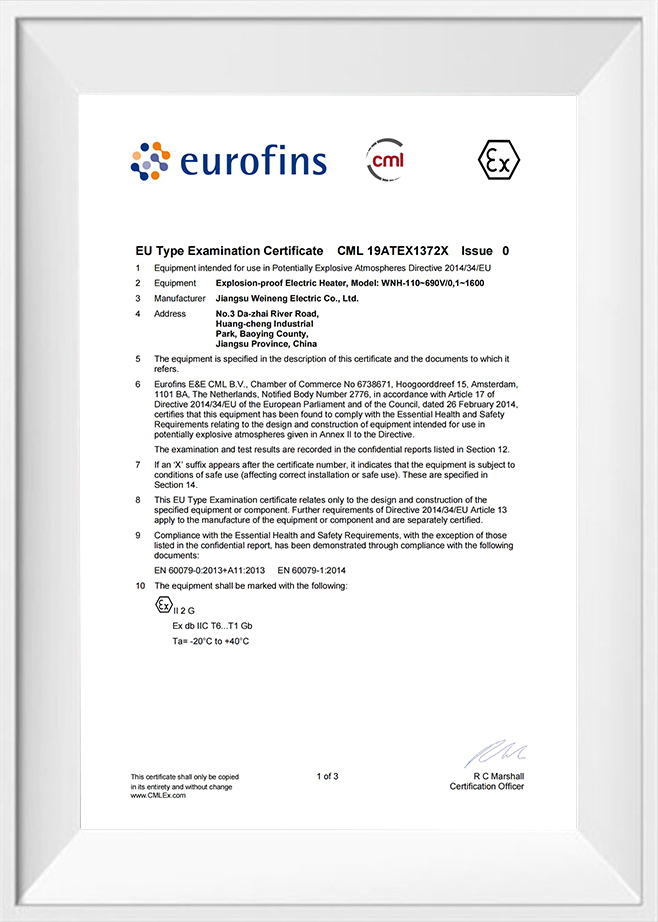

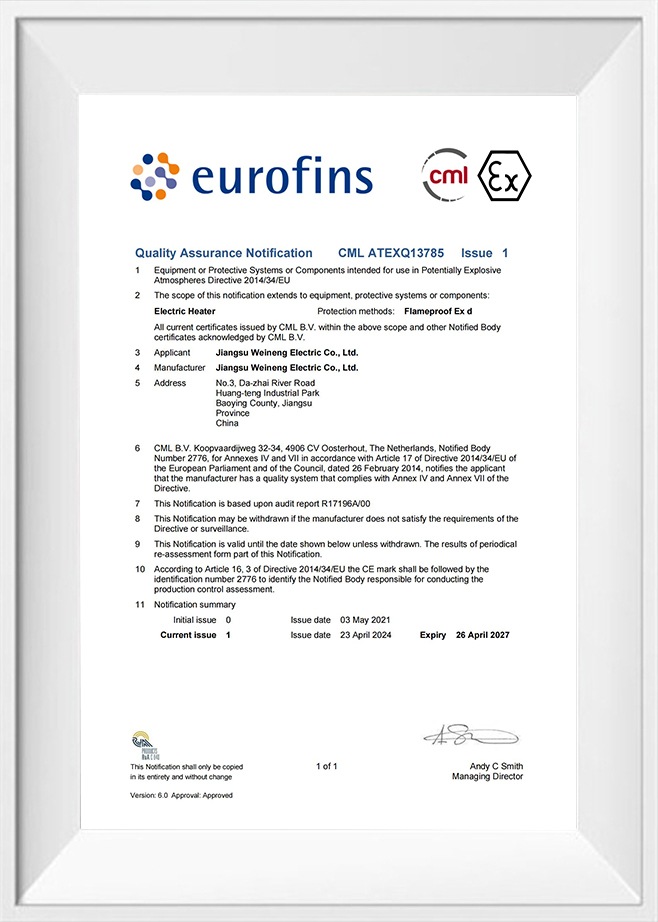

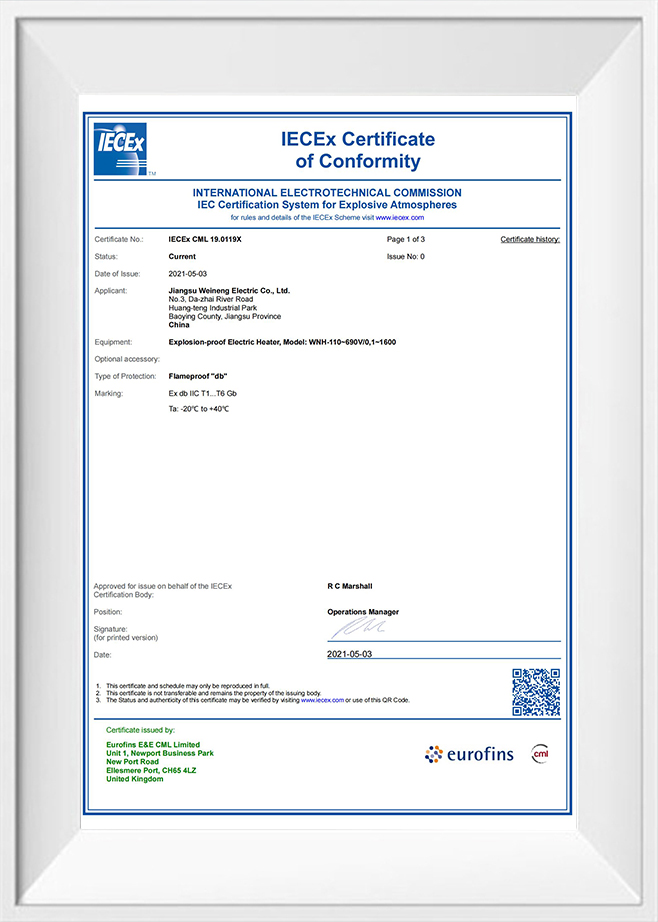

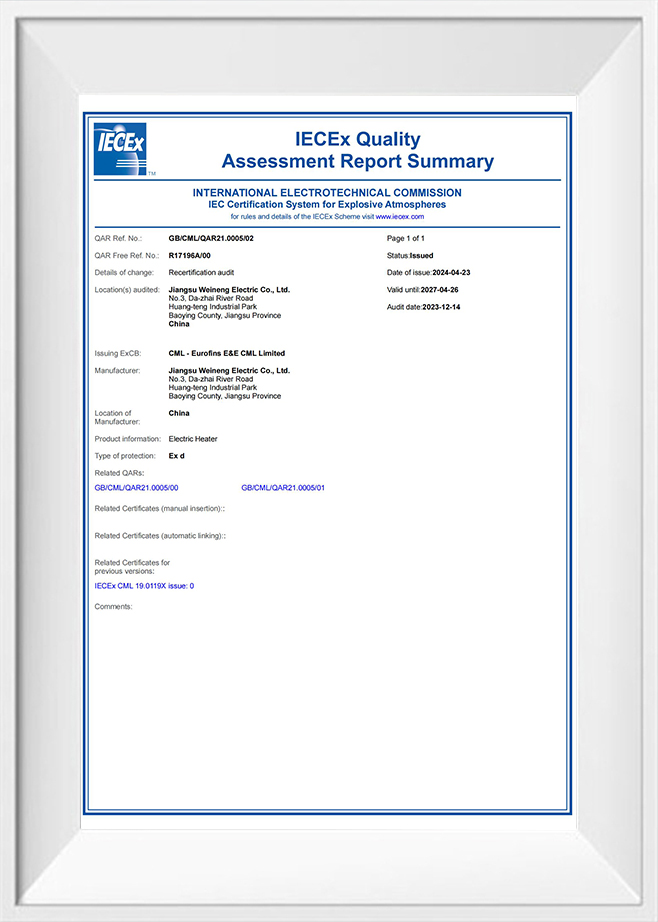

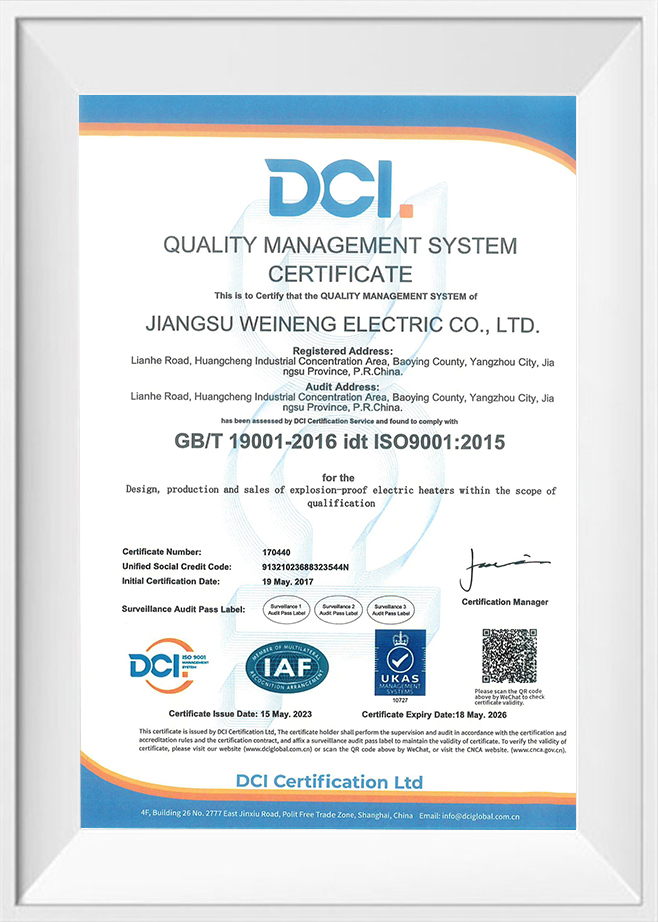

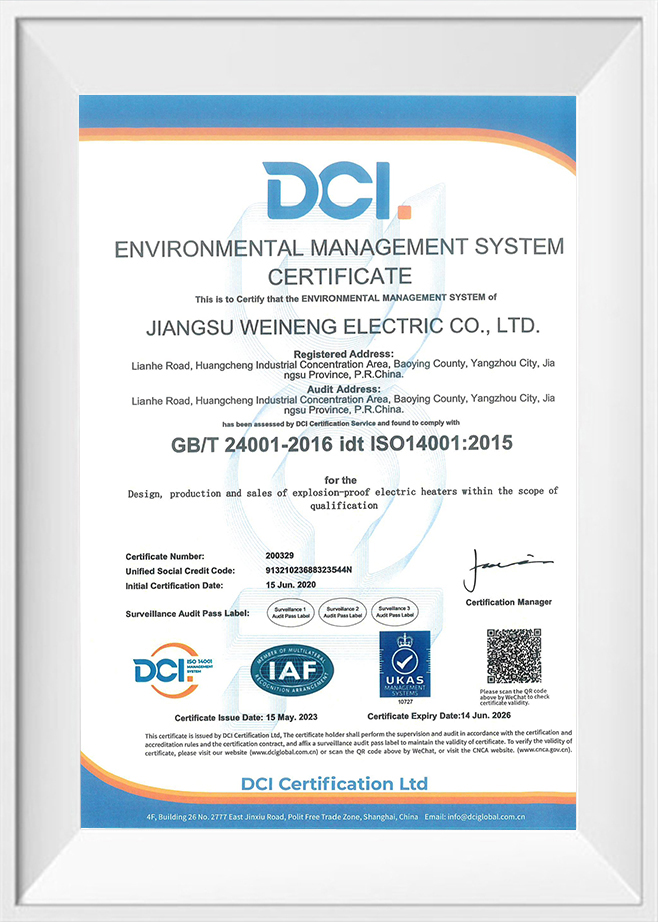

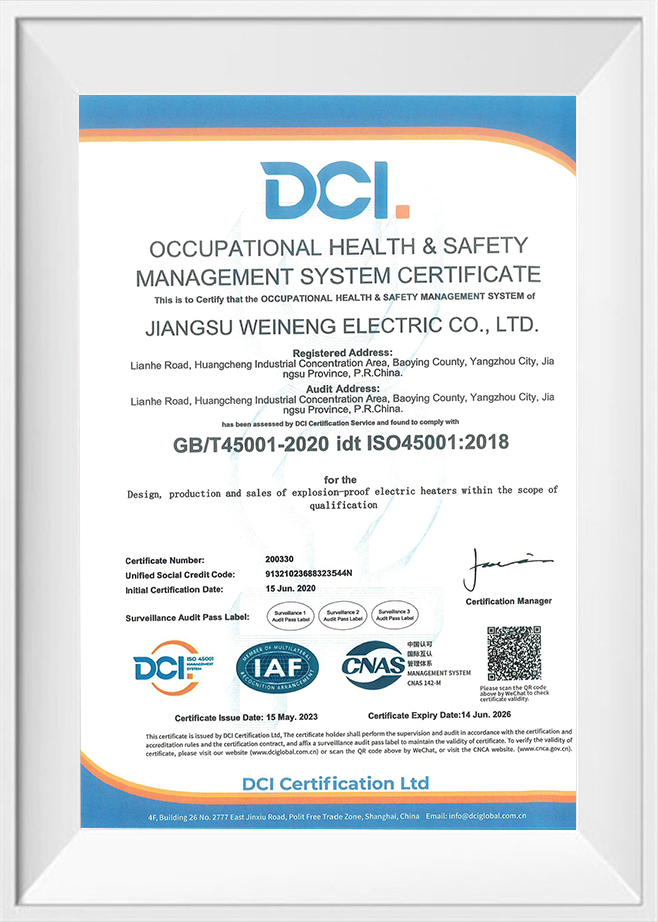

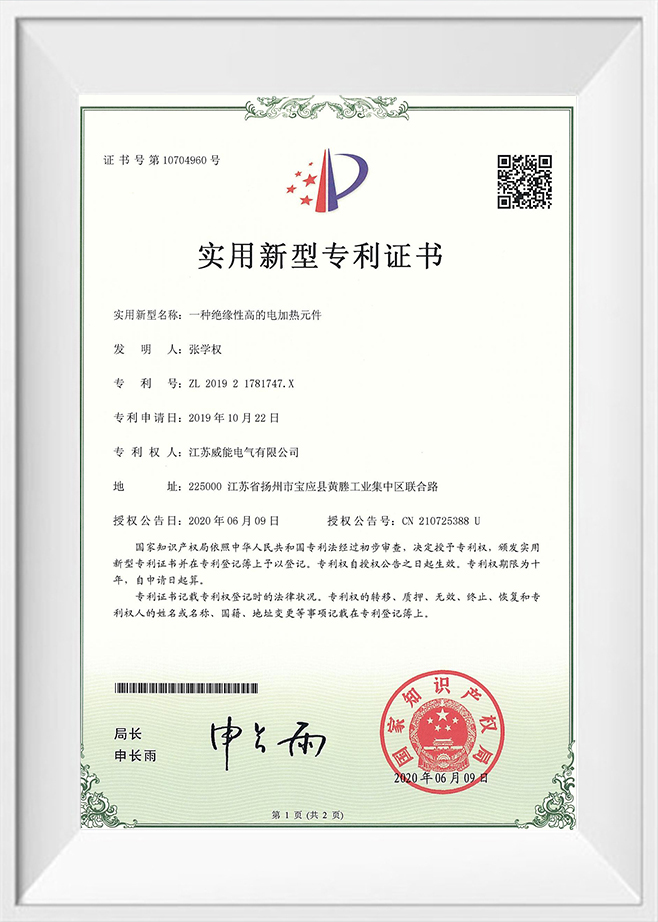

As China Industrial Skid Heaters Manufacturers and Industrial Skid Heater Factory, We are located in Baoying County,Jiangsu Province with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including power filling machine,electric pressure test pump,gauge lathe,LCD spot welding machine,drying cabinet,cleaning machine,dry sand blasting machine,automatic pipebender,digital multimeter,insulation resistance meter,voltage-resistant tester. Our company insist in technological innovation,we have 3 professors of engineering and dozens of young engineers with rich experience to orgonized a professional engineering team.We cooperate with universities and academies to research and develop new product. In addition, we have obtained IEcEx,Attex,ISO certificates.Selling well in all cities and provinces around China, We offer Custom Industrial Skid Heater. our products are also exported to clients in such countries and regions as Middle East,Southeast Asia ,America and Europe. We also welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.Learn about our industry exhibition information and recent events in our company.

-

Explosion Proof Electrical Connectors: Selection & Safety Guide

What Explosion Proof Electrical Connectors Actually Do Explosion proof electrical connectors are not designed to prevent an internal spark or arc — t...25 -

Air Duct Heaters: Efficient HVAC Heating Solutions

Air Duct Heaters Deliver Targeted, Energy-Efficient Heating Directly Within HVAC Systems Air duct heaters are electric heating elements installed ins...19 -

Air Duct Heaters for Efficient HVAC Temperature Control

Air Duct Heaters as a Practical Heating Solution Air duct heaters are an efficient and controllable way to raise or stabilize air temperature directl...09 -

Electric Immersion Heater: Types, Uses & Safety Tips

Electric Immersion Heater: Quick Overview and Conclusion Electric immersion heaters are highly efficient devices for heating liquids directly in tank...05 -

Can Upgrading Process Heaters Boost Manufacturing Competitiveness?

The Role of Process Heaters in Modern Manufacturing Process heaters are critical components in industrial operations, providing the controlled heat ne...30

The Role of Electric Skid Heaters in Industrial Thermal Management Systems

Electric skid heaters play a critical role in modern industrial thermal management systems. Designed to deliver reliable and efficient heating solutions, these units are often used in industries that demand precise control over temperature-sensitive processes. Also referred to as industrial skid heaters, these systems integrate heating elements, control systems, and auxiliary equipment into a compact, pre-assembled skid unit, significantly simplifying installation and maintenance for demanding industrial applications.

What Is an Electric Skid Heater?

An electric skid heater is a fully integrated and modular heating solution designed for fluid temperature control in industrial environments. It consists of electric heating elements housed within a skid-mounted structure, which also includes components such as pumps, valves, sensors, programmable logic controllers (PLCs), and monitoring instruments. These heaters are engineered to meet specific thermal and flow requirements, offering targeted heat transfer with high precision and safety.

The industrial skid heater concept is particularly valuable because of its versatility. It is not limited to a single industry or application. Whether used for maintaining the temperature of crude oil in pipelines, heating process water in power plants, or managing fluid temperatures in chemical injection systems, these systems deliver consistent and energy-efficient performance.

Application Across Industries

Electric skid heaters have become essential components across a wide range of industries, including oil and gas, petrochemical, power generation, water treatment, and more. In these sectors, thermal management is critical to ensure safe, reliable, and energy-efficient operations. For example, in the oil and gas industry, maintaining optimal fluid temperatures can improve flow properties and reduce processing time. In power generation, precise heat control helps in maintaining boiler feedwater temperatures and supports efficient turbine operation.

In chemical processing, where reactions are highly sensitive to temperature fluctuations, an electric skid heater provides the stability needed to prevent deviations that could lead to poor product quality or safety hazards. These heaters are also ideal for installations where space is limited or rapid deployment is required, as their modular design allows for easy transportation, installation, and scalability.

Technical Features and Performance

Modern electric skid heaters are equipped with advanced features that enhance their performance and reliability. These features often include digital control systems, real-time temperature and pressure monitoring, automatic safety interlocks, and remote operation capabilities. The use of programmable logic controllers (PLCs) allows for automation and data integration with other plant control systems, providing operators with full visibility and control of thermal processes.

The skid-mounted design not only reduces the footprint but also minimizes on-site installation time. As all key components are pre-assembled and tested at the factory, commissioning time is significantly reduced, allowing industrial plants to achieve operational readiness faster. Maintenance is also simplified, as components are organized and accessible within the skid frame.

Jiangsu Weineng operates with a strong focus on quality control and customer satisfaction. The company’s engineering team includes three professors of engineering and numerous young engineers with rich experience in industrial heating technology. This skilled team collaborates closely with universities and research institutes to continually develop new and improved products tailored to evolving industry needs.

To support its manufacturing capabilities, the company has invested in a wide array of advanced equipment, such as electric pressure test pumps, LCD spot welding machines, automatic pipe benders, insulation resistance meters, and voltage-resistant testers. These facilities enable Jiangsu Weineng to deliver high-quality products that meet stringent international standards, including IECEx, ATEX, and ISO certifications.

Meeting Global Demand with Customized Solutions

Jiangsu Weineng’s industrial skid heaters are customized to meet the specific requirements of different industries and applications. Whether the demand involves high pressure, fluctuating temperatures, or corrosive media, the company offers tailor-made heating solutions that perform reliably under challenging conditions. Their heaters are well-received in both domestic and international markets, with clients across the Middle East, Southeast Asia, Europe, and America. The company also supports OEM and ODM orders, making it a flexible partner for global businesses.

By integrating all critical components into a single skid-mounted unit, Jiangsu Weineng’s electric skid heaters reduce the complexity of thermal management projects and ensure a shorter lead time from project initiation to system commissioning. This approach not only reduces project costs but also improves overall system efficiency.

|

As industries continue to demand more efficient, reliable, and integrated thermal management systems, the importance of electric skid heaters and industrial skid heaters will only grow. Their compact, customizable design, advanced control features, and ease of installation make them indispensable tools for process heating across a wide range of sectors. Companies like Jiangsu Weineng Electric Co., Ltd are at the forefront of this innovation, delivering smart, scalable solutions that meet the evolving thermal challenges of industrial environments.

Whether your application lies in oil and gas, power generation, water treatment, or chemical processing, an electric skid heater offers the performance, safety, and flexibility to support critical operations efficiently.

English

English русский

русский Français

Français Español

Español عربى

عربى