Hot Water Storage Screw Plug Immersion Heater is a highly efficient and reliable solution for direct...

Screw Plug Immersion Heater Manufacturers

-

-

Cooling Tower Screw Plug Immersion Heater

Cooling Tower Screw Plug Immersion HeaterThe Cooling Tower Screw Plug Immersion Heater is a highly efficient and reliable heating solution de...

-

Mildly Corrosive Liquids Screw Plug Immersion Heater

Mildly Corrosive Liquids Screw Plug Immersion HeaterThe Hot Water Storage Screw Plug Immersion Heater is a compact, energy-efficient solution designed f...

-

Heavy Oil Screw Plug Immersion Heater

Heavy Oil Screw Plug Immersion HeaterHeavy Oil Screw Plug Immersion Heater is a compact, energy-efficient heating solution specifically e...

-

Soluble Cutting Oil Screw Plug Immersion Heater

Soluble Cutting Oil Screw Plug Immersion HeaterThe Soluble Cutting Oil Screw Plug Immersion Heater is a compact, energy-efficient solution designed...

Screw Plug Immersion Heater is a versatile and efficient heating solution designed to meet the demands of a wide range of industrial, commercial, and specialized applications. Compact and energy-efficient, it provides reliable, direct immersion heating for liquids such as clean water, oils, gases, process water, and mildly to severely corrosive solutions. Its robust design features custom-engineered heating elements securely integrated into the screw plug, ensuring compatibility with diverse materials, including demineralized water, heavy oils, and soluble cutting oils.

Built for convenience and safety, this heater is easy to install, remove, and maintain, minimizing operational disruptions and maintenance costs. Optional thermostats enable precise temperature regulation, while standard or specialized enclosures—such as moisture-resistant, explosion-proof, or combination options—ensure safe operation in challenging environments. From freeze protection and hot water storage to steam boilers, cooling towers, and food equipment, the Screw Plug Immersion Heater delivers consistent, uniform heating and long-lasting performance.

Customizable to suit specific application needs, this heater combines durability, adaptability, and efficiency, making it an essential tool for industries requiring dependable and precise heating solutions. Whether used for process water, detergents, light or heavy oils, or even severe corrosive liquids, the Screw Plug Immersion Heater stands out as a reliable and adaptable choice for diverse heating challenges.

Jiangsu Weineng Electric Co.,Ltd established in April 23rd,2009, is a professional manufacturer engaged in the research, development, production, sale and service of Electric Heaters,Electric Heat Tracing Cable and Control system for industry.

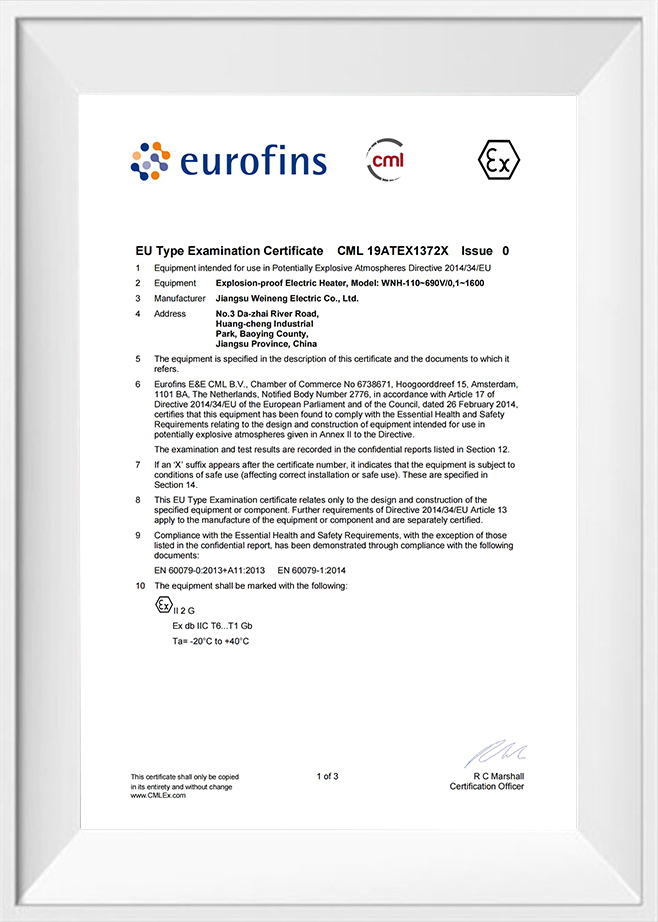

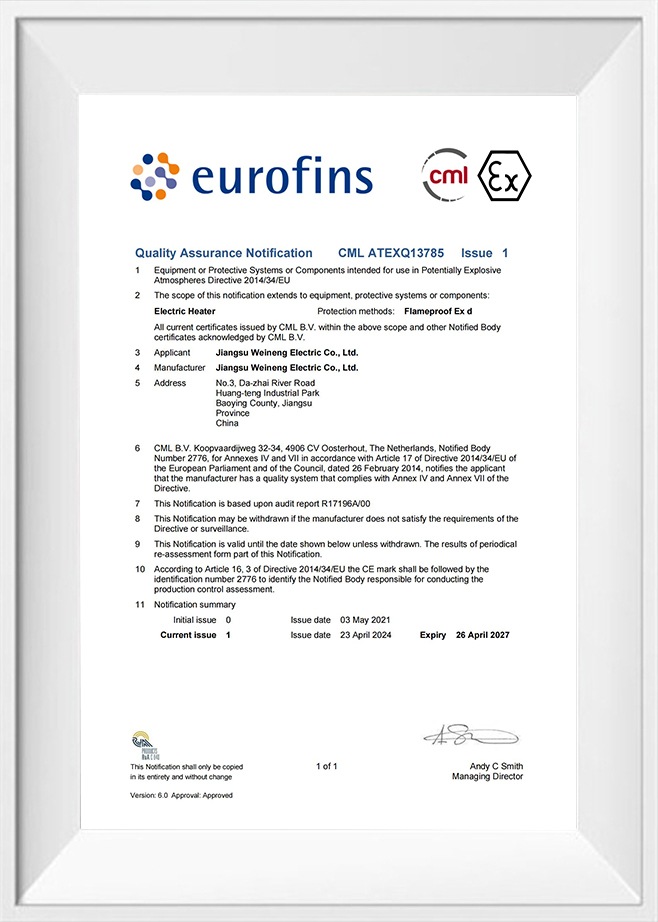

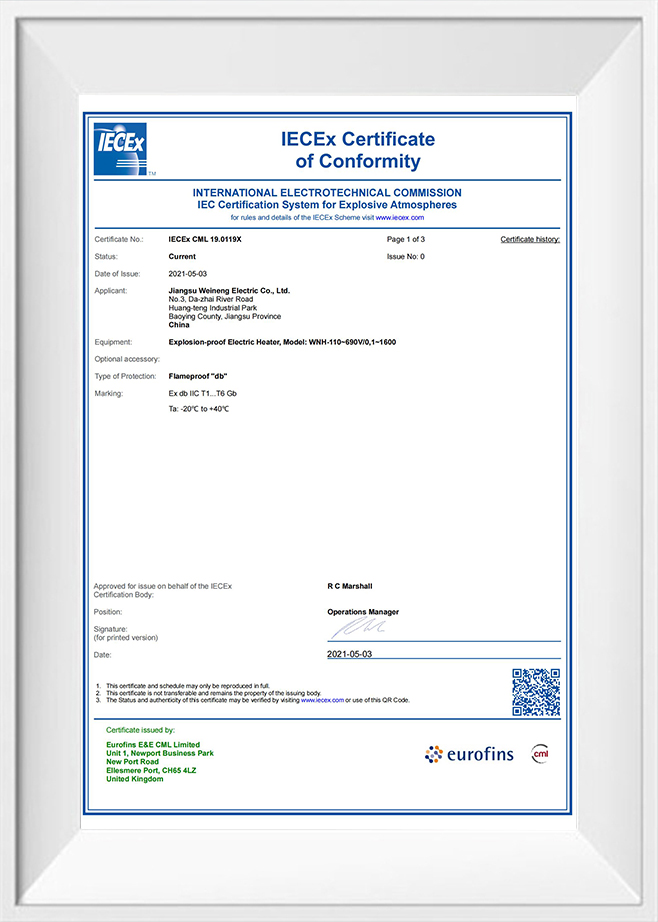

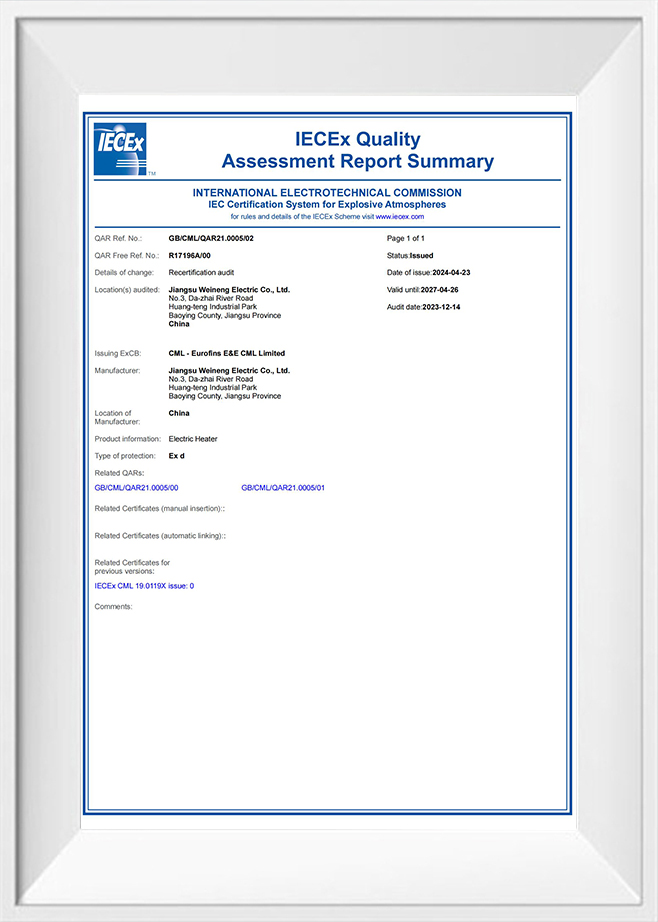

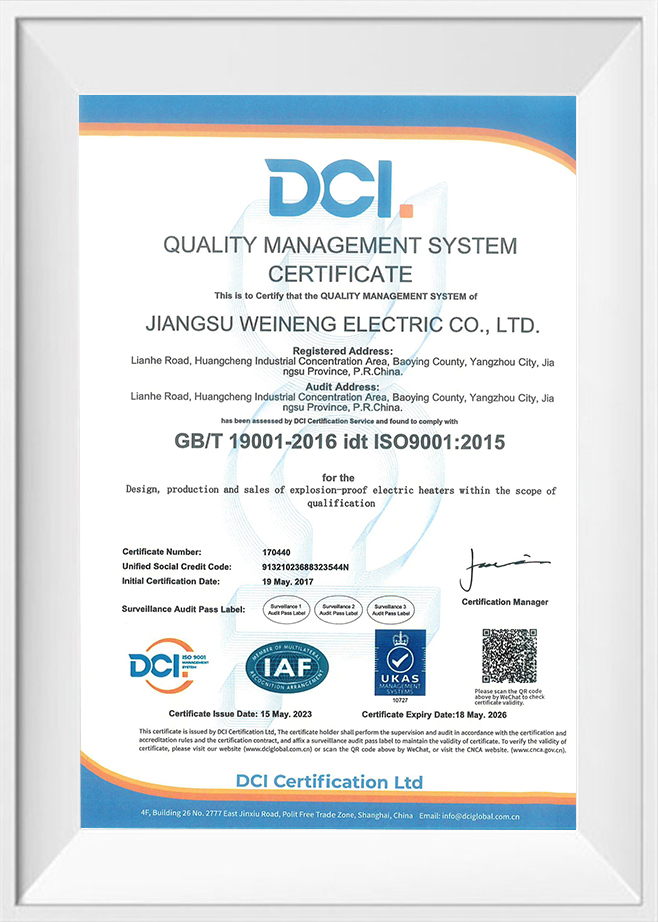

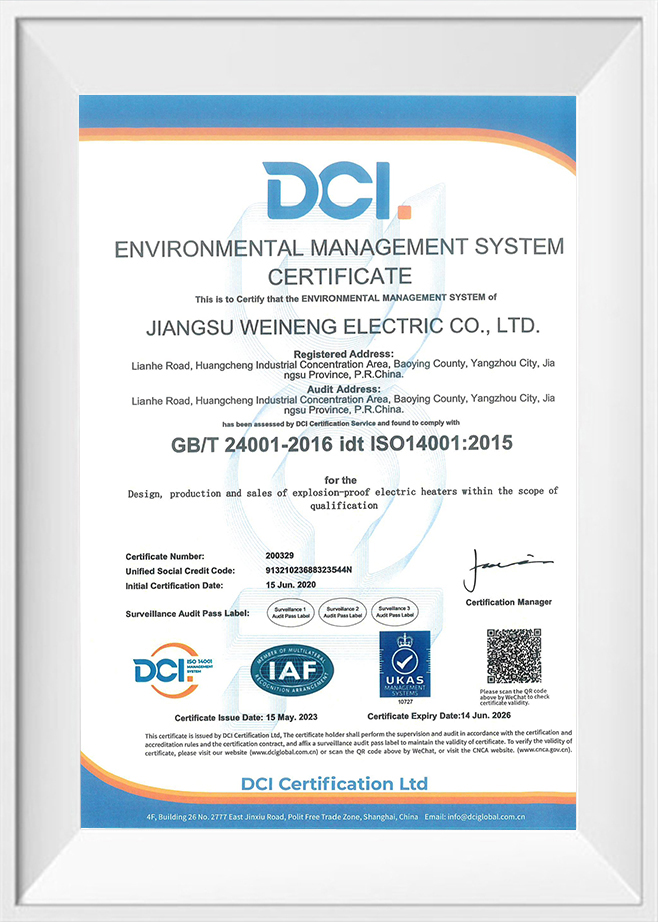

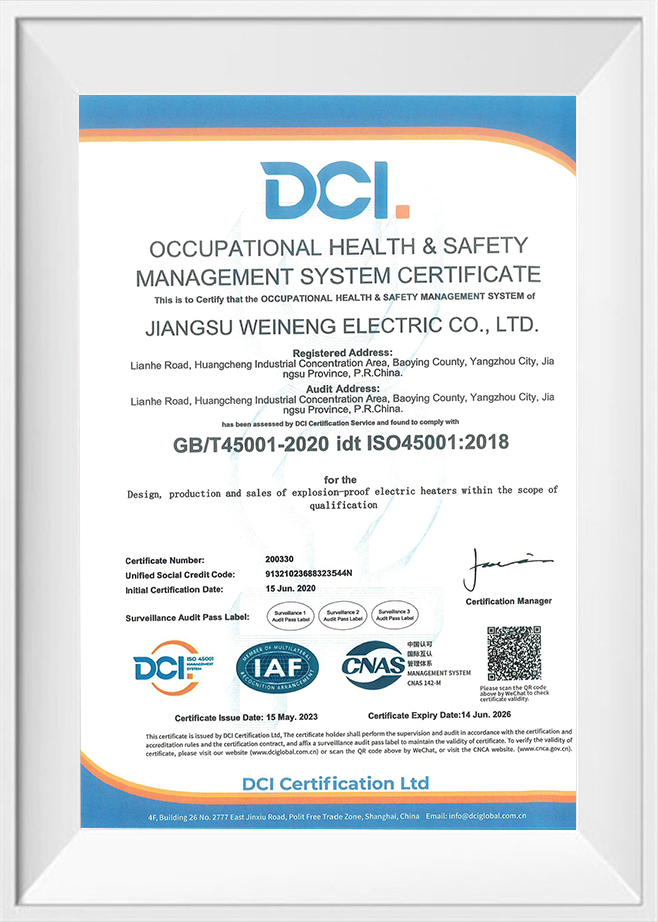

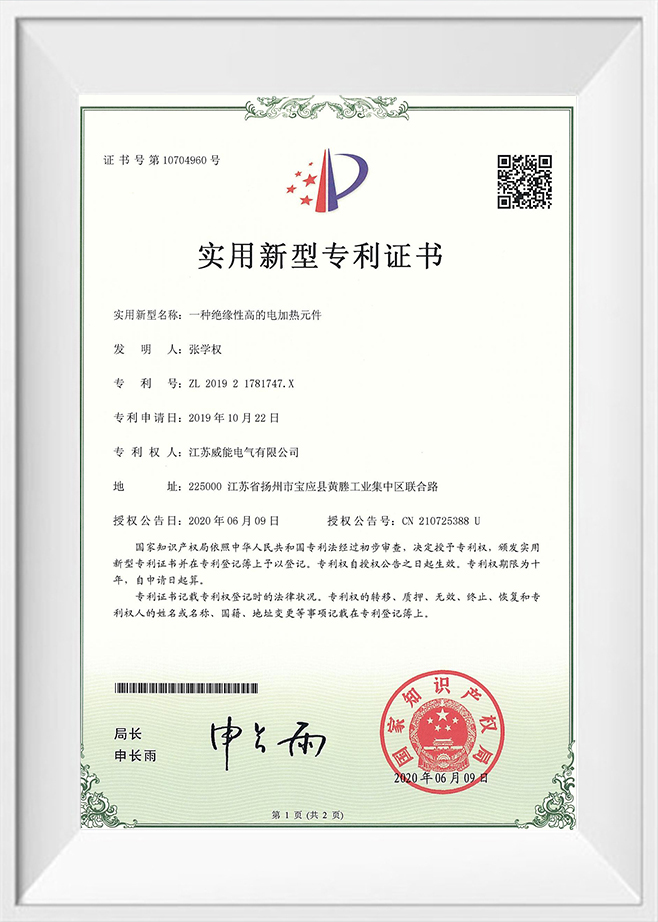

As China Screw Plug Immersion Heater Manufacturers and Screw Plug Immersion Heater Factory, We are located in Baoying County,Jiangsu Province with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including power filling machine,electric pressure test pump,gauge lathe,LCD spot welding machine,drying cabinet,cleaning machine,dry sand blasting machine,automatic pipebender,digital multimeter,insulation resistance meter,voltage-resistant tester. Our company insist in technological innovation,we have 3 professors of engineering and dozens of young engineers with rich experience to orgonized a professional engineering team.We cooperate with universities and academies to research and develop new product. In addition, we have obtained IEcEx,Attex,ISO certificates.Selling well in all cities and provinces around China, We offer Custom Screw Plug Immersion Heater. our products are also exported to clients in such countries and regions as Middle East,Southeast Asia ,America and Europe. We also welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.Learn about our industry exhibition information and recent events in our company.

-

Explosion Proof Electrical Connectors: Selection & Safety Guide

What Explosion Proof Electrical Connectors Actually Do Explosion proof electrical connectors are not designed to prevent an internal spark or arc — t...25 -

Air Duct Heaters: Efficient HVAC Heating Solutions

Air Duct Heaters Deliver Targeted, Energy-Efficient Heating Directly Within HVAC Systems Air duct heaters are electric heating elements installed ins...19 -

Air Duct Heaters for Efficient HVAC Temperature Control

Air Duct Heaters as a Practical Heating Solution Air duct heaters are an efficient and controllable way to raise or stabilize air temperature directl...09 -

Electric Immersion Heater: Types, Uses & Safety Tips

Electric Immersion Heater: Quick Overview and Conclusion Electric immersion heaters are highly efficient devices for heating liquids directly in tank...05 -

Can Upgrading Process Heaters Boost Manufacturing Competitiveness?

The Role of Process Heaters in Modern Manufacturing Process heaters are critical components in industrial operations, providing the controlled heat ne...30

How Does Jiangsu Weineng Electric Co., Ltd Ensure Good Insulation Around the Screw Plug Immersion Heater?

When it comes to industrial heating, insulation isn’t just a detail—it’s a critical safeguard. It protects personnel, preserves energy, and prolongs the operational life of equipment. Nowhere is this more essential than in the design and performance of Screw Plug Immersion Heaters, where electrical safety, thermal control, and durability converge. At the forefront of this engineering challenge stands Jiangsu Weineng Electric Co., Ltd, a name synonymous with precision, innovation, and unwavering quality.

Founded on April 23, 2009, Jiangsu Weineng Electric Co., Ltd has carved a niche as a specialized manufacturer of Electric Heaters, Electric Heat Tracing Cables, and Intelligent Control Systems. From its strategic base in Baoying County, Jiangsu Province, the company operates a sophisticated production facility equipped with state-of-the-art technology—automatic pipe benders, electric pressure test pumps, drying cabinets, and digital insulation resistance meters, to name a few. These aren’t just tools—they’re part of an ecosystem designed to deliver uncompromised safety and thermal efficiency.

So, how does this powerhouse ensure excellent insulation around its Screw Plug Immersion Heaters?

Meticulous Design, Material Selection, and Engineering Integration

The insulation process begins at the core—literally. Jiangsu Weineng integrates high-grade electrical insulation materials such as magnesium oxide (MgO) within its tubular heating elements. This compound, renowned for its thermal conductivity and dielectric strength, is densely packed around the heating coil inside the sheath, ensuring both heat transfer and electrical insulation are achieved without compromise.

The entire heating element is securely embedded into a robust screw plug—typically forged from stainless steel or brass—to create a leak-tight seal. This not only facilitates direct immersion but also reinforces mechanical and electrical isolation from the process fluid. Whether submerged in demineralized water, viscous oils, or corrosive chemicals, this insulation strategy maintains system integrity and personnel safety.

Advanced Testing and Certification Protocols

Good insulation isn’t a claim—it’s a measurement. Jiangsu Weineng subjects every Screw Plug Immersion Heater to stringent insulation resistance tests using digital multimeters and voltage-resistant testers. Each unit must meet or exceed international insulation benchmarks before it leaves the facility. The company’s commitment to quality is validated by globally recognized certifications, including IECEx, ATEX, and ISO, which reinforce its ability to deliver explosion-proof and corrosion-resistant solutions for high-risk environments.

Specialized Enclosures and Safety Enhancements

Insulation isn’t limited to the heating element—it extends to the external protection as well. Jiangsu Weineng offers a selection of engineered enclosures—including moisture-resistant, explosion-proof, and weather-sealed housings—which shield the terminals and wiring connections. These enclosures act as a second layer of insulation, guarding against external contaminants, humidity, and accidental contact.

For clients operating in volatile environments—chemical plants, offshore rigs, refineries—this additional layer of insulation is not only recommended but often mandatory. By integrating thermostatic controls and over-temperature protection, Jiangsu Weineng ensures that every heater is not only efficient but also exceptionally safe.

Expertise, Innovation, and Customization

The company’s advantage lies not only in its equipment but in its people. Jiangsu Weineng has assembled a formidable engineering team, including three senior professors and a cadre of young, field-hardened engineers. This blend of academic depth and practical experience fuels its ongoing collaboration with leading universities and technical institutions. Together, they develop new insulation techniques, test advanced materials, and continuously refine safety protocols.

This focus on technological innovation enables the company to offer fully customized Screw Plug Immersion Heaters. Whether a client requires insulation adapted to cryogenic fluids, high-viscosity petrochemicals, or aggressive alkalis, Jiangsu Weineng delivers bespoke solutions without sacrificing lead times or quality assurance.

Global Reach, Local Precision

While firmly rooted in China, Jiangsu Weineng’s heaters power industries across the Middle East, Southeast Asia, Europe, and the Americas. From freeze protection in northern climates to high-temperature process heating in tropical zones, the company’s heaters perform under pressure—insulated, protected, and uncompromisingly reliable.

OEM and ODM support is not just available—it’s encouraged. Clients can source directly from cataloged models or work hand-in-hand with the technical team to develop a heater that fits their application like a glove.

Good insulation around a Screw Plug Immersion Heater isn’t just about wrapping wires—it’s a sophisticated interplay of engineering precision, quality materials, rigorous testing, and purpose-built design. Jiangsu Weineng Electric Co., Ltd delivers this with conviction, ensuring that every heater it produces is as safe as it is powerful. For industries where thermal control is mission-critical, this isn’t a luxury—it’s a necessity.

English

English русский

русский Français

Français Español

Español عربى

عربى