Flange Type Storage Tank Immersion Heater is a high-performance heating solution designed for effici...

Flange Immersion Heater Manufacturers

-

-

Industrial Fluids Flange Type Immersion Heater

Industrial Fluids Flange Type Immersion HeaterIndustrial Fluids Flange Type Immersion Heater is a robust and efficient solution for heating liquid...

-

Large Container Flange Type Immersion Heater

Large Container Flange Type Immersion HeaterLarge Container Flange Type Immersion Heater is a durable and efficient solution for heating liquids...

-

Easy installation Flange Immersion Heater

Easy installation Flange Immersion HeaterEasy Installation Flange Immersion Heater is a robust and efficient solution designed for reliable h...

-

Drain Drum Flange Immersion Heater

Drain Drum Flange Immersion HeaterDrain Drum Flange Immersion Heater is a robust and efficient solution for tank heating applications,...

-

Industrial Vessel Flange Immersion Heater

Industrial Vessel Flange Immersion HeaterIndustrial Vessel Flange Immersion Heater is a robust and efficient heating solution designed for us...

-

Lube Oil Reservoir Flange Immersion Heater

Lube Oil Reservoir Flange Immersion HeaterThe Lube Oil Reservoir Flange Immersion Heater is a high-performance heating solution designed for e...

Flange Immersion Heaters are robust, versatile heating solutions designed for direct immersion into tanks, vessels, or containers to efficiently heat liquids, oils, gases, and viscous fluids. These heaters are widely used in industrial applications where reliable and precise heating is required, such as storage tanks, process fluids, lube oil reservoirs, and chemical processing. Featuring a flanged connection for easy installation and maintenance, they ensure consistent heat distribution and energy transfer. Constructed from high-quality materials like Inconel, Incoloy, Hastelloy, Titanium, and Stainless Steel, Flange Immersion Heaters offer exceptional resistance to corrosion and high temperatures. Certified for hazardous environments (ATEX, IECEx) and equipped with advanced safety features such as over-temperature protection and ingress protection (IP65/IP66), they are suitable for safe operation in Zone 1 & 2 applications. With customizable wattages, voltages, and configurations, these heaters are engineered to meet ASME code and international standards, ensuring durability and performance in both cyclic and continuous operation. Whether heating large tanks, underground reservoirs, or process fluids, Flange Immersion Heaters deliver efficient, reliable, and safe heating for a wide range of industrial needs.

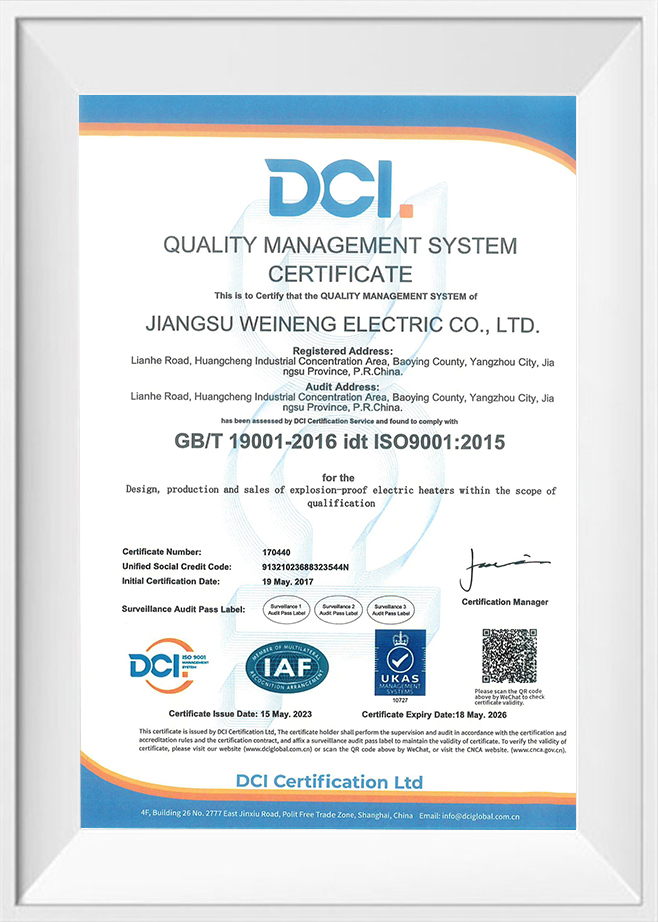

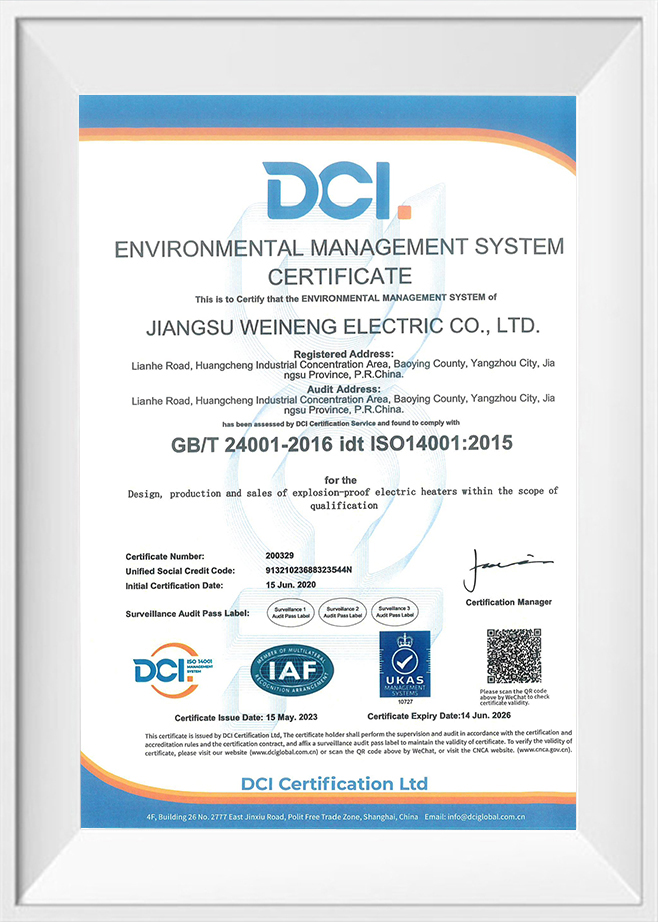

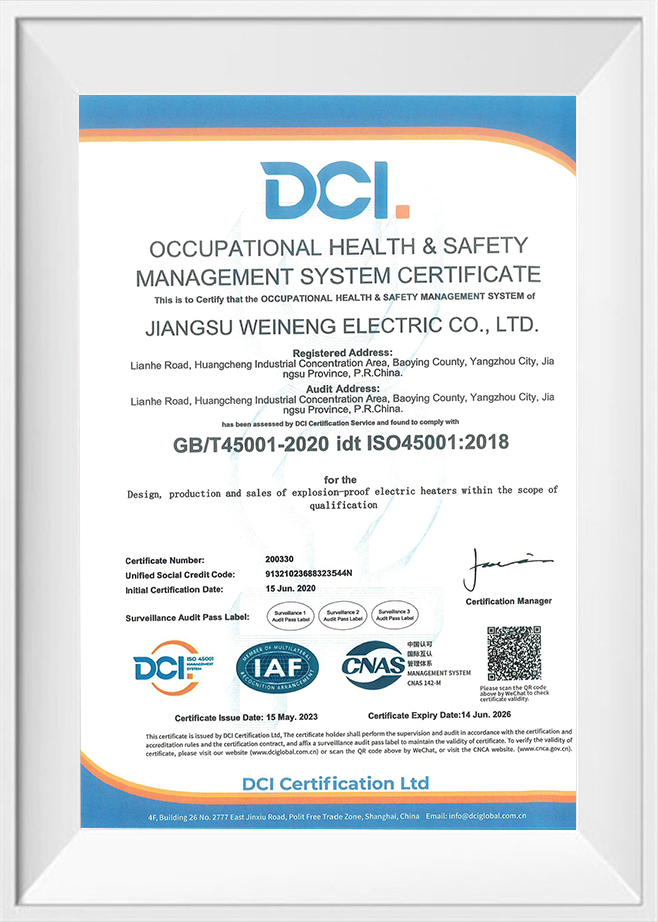

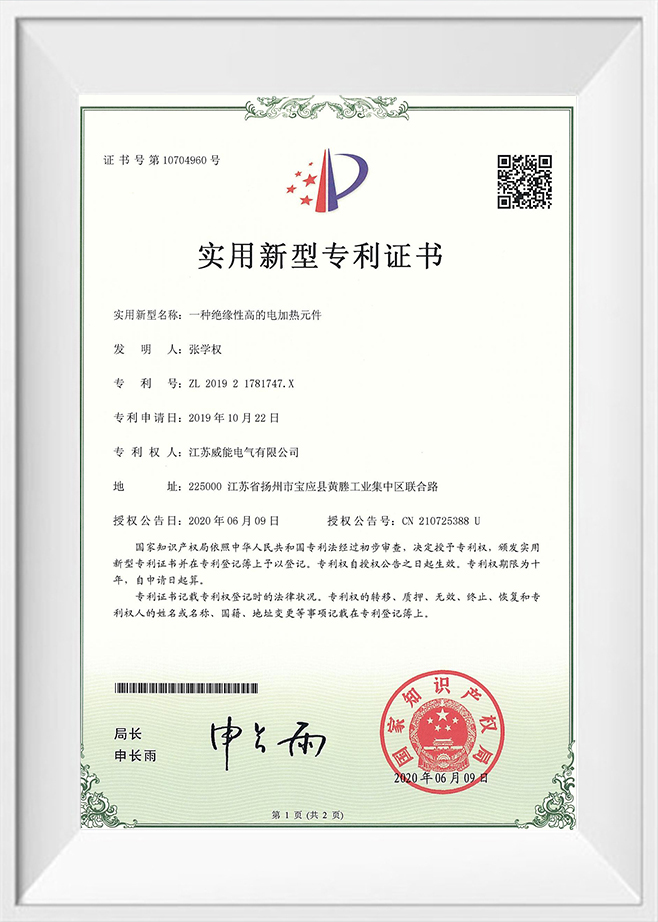

Jiangsu Weineng Electric Co.,Ltd established in April 23rd,2009, is a professional manufacturer engaged in the research, development, production, sale and service of Electric Heaters,Electric Heat Tracing Cable and Control system for industry.

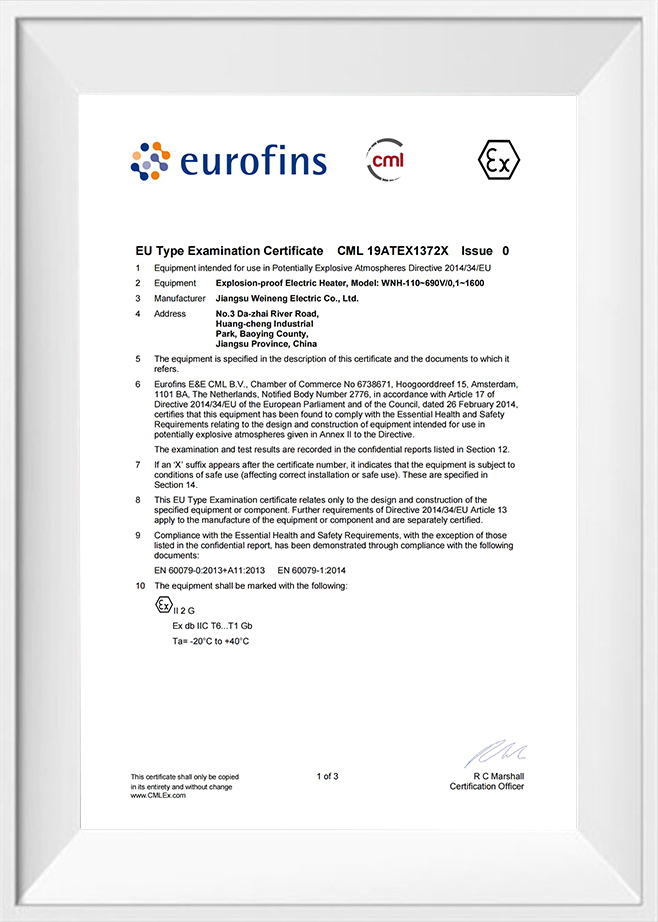

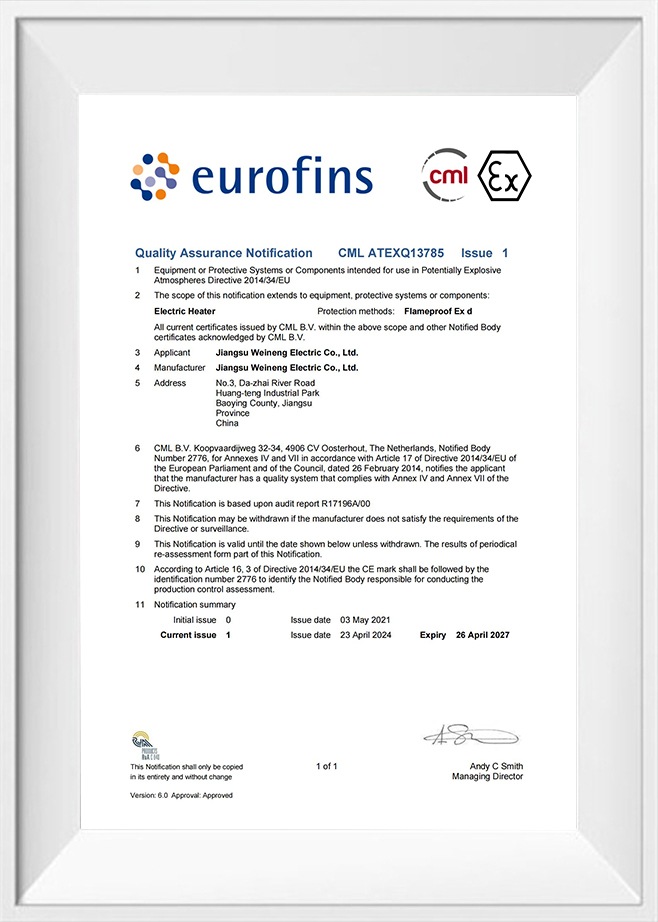

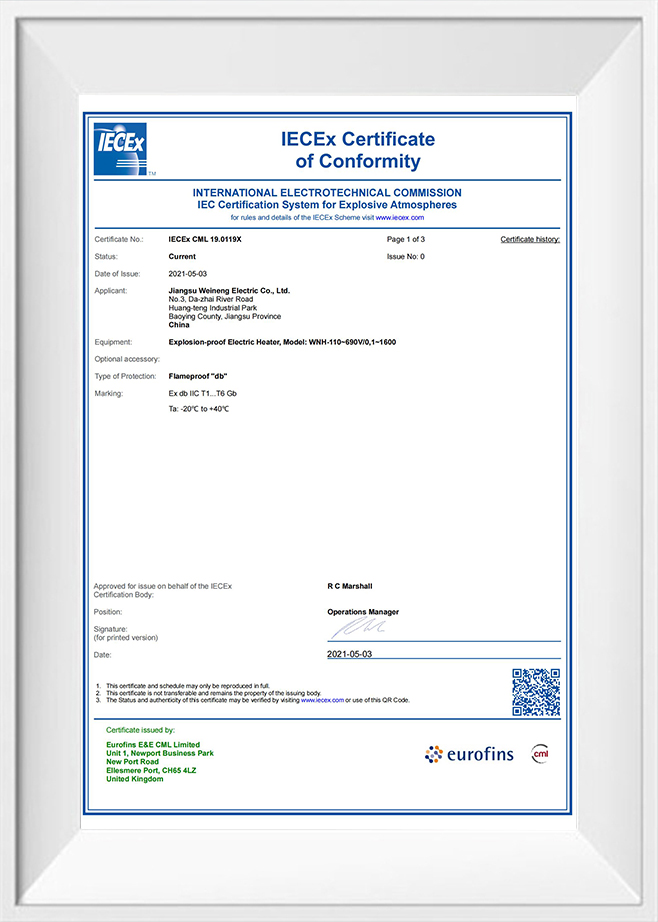

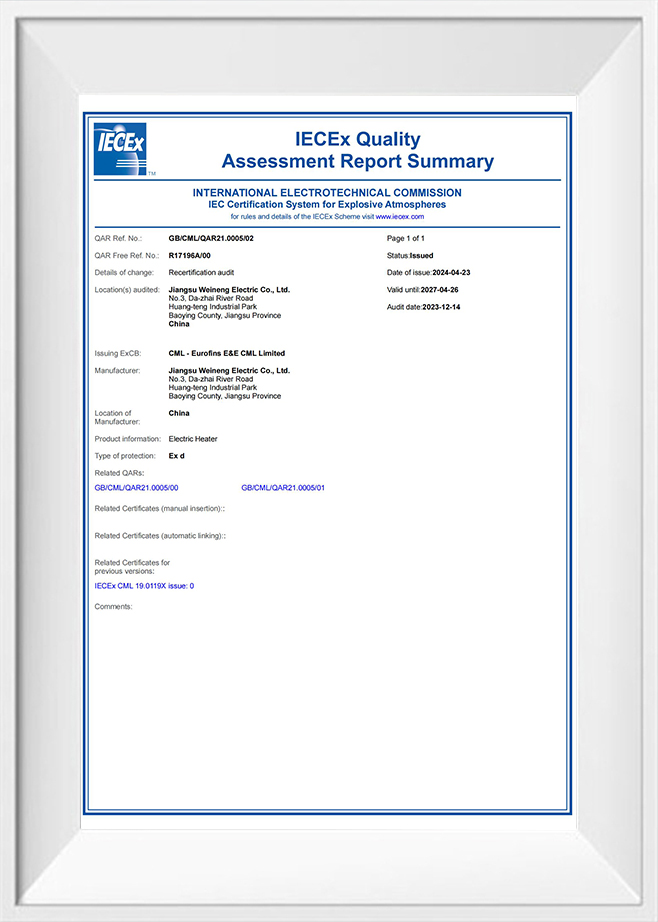

As China Flange Immersion Heater Manufacturers and Flange Immersion Heater Factory, We are located in Baoying County,Jiangsu Province with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including power filling machine,electric pressure test pump,gauge lathe,LCD spot welding machine,drying cabinet,cleaning machine,dry sand blasting machine,automatic pipebender,digital multimeter,insulation resistance meter,voltage-resistant tester. Our company insist in technological innovation,we have 3 professors of engineering and dozens of young engineers with rich experience to orgonized a professional engineering team.We cooperate with universities and academies to research and develop new product. In addition, we have obtained IEcEx,Attex,ISO certificates.Selling well in all cities and provinces around China, We offer Custom Flange Immersion Heater. our products are also exported to clients in such countries and regions as Middle East,Southeast Asia ,America and Europe. We also welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.Learn about our industry exhibition information and recent events in our company.

-

Explosion Proof Electrical Connectors: Selection & Safety Guide

What Explosion Proof Electrical Connectors Actually Do Explosion proof electrical connectors are not designed to prevent an internal spark or arc — t...25 -

Air Duct Heaters: Efficient HVAC Heating Solutions

Air Duct Heaters Deliver Targeted, Energy-Efficient Heating Directly Within HVAC Systems Air duct heaters are electric heating elements installed ins...19 -

Air Duct Heaters for Efficient HVAC Temperature Control

Air Duct Heaters as a Practical Heating Solution Air duct heaters are an efficient and controllable way to raise or stabilize air temperature directl...09 -

Electric Immersion Heater: Types, Uses & Safety Tips

Electric Immersion Heater: Quick Overview and Conclusion Electric immersion heaters are highly efficient devices for heating liquids directly in tank...05 -

Can Upgrading Process Heaters Boost Manufacturing Competitiveness?

The Role of Process Heaters in Modern Manufacturing Process heaters are critical components in industrial operations, providing the controlled heat ne...30

How to Maintain and Extend the Service Life of Your Industrial Flange Immersion Heater System

In industrial heating systems, long-term performance and safety go hand in hand with well-planned maintenance. A Flange Immersion Heater is built to withstand extreme environments, but like any critical equipment, its reliability over time depends heavily on proper inspection and upkeep. Regular maintenance not only ensures consistent heating performance but also helps prevent costly downtime in applications ranging from chemical processing to oil storage.

The key to effective heater maintenance is understanding the operational stresses these units endure. A Flange Immersion Heater operates under high temperatures and often in corrosive or viscous media. Over time, even high-grade alloys such as Incoloy or Hastelloy can suffer from scale buildup, corrosion, or metal fatigue—especially in environments with fluctuating fluid properties. That’s why we recommend scheduling inspections based on both operating hours and fluid conditions rather than using fixed intervals alone.

One of the most overlooked aspects of maintenance is the buildup of mineral deposits or carbonization on the sheath surface, which significantly reduces heat transfer efficiency. In high-viscosity or oil-based applications, this buildup can also lead to localized overheating, resulting in premature failure of the heating element. Periodic cleaning and, where appropriate, the use of sheath coatings can mitigate this issue. Choosing the correct watt density at the design stage can also reduce maintenance frequency and extend the life of your Flange Immersion Heater.

Electrical and safety systems should never be an afterthought. Regularly checking terminal enclosures, temperature sensors, and control panels is essential, particularly for units installed in hazardous locations (Zone 1 or 2). If your heater is certified under ATEX or IECEx standards, any maintenance or component replacement must maintain those compliance requirements. It’s also wise to ensure that ingress protection ratings like IP65 or IP66 are preserved during servicing, especially in outdoor or washdown environments.

Thermowells, gaskets, and flange connections are often subjected to mechanical stress during thermal cycles. These components must be inspected for wear, cracking, or seal failure, as even minor leakage can affect system efficiency or safety. In continuous process environments, a scheduled replacement plan—rather than waiting for signs of failure—can reduce unscheduled downtime and make your maintenance program more predictable and cost-effective.

We’ve seen that clients who adopt a preventive maintenance mindset tend to maximize their return on investment. A Flange Immersion Heater may be built for durability, but even the highest quality system benefits from strategic monitoring. Integration with automated control systems can offer predictive alerts for temperature deviations or abnormal power draw, enabling smarter maintenance decisions before problems escalate.

As a manufacturer with years of hands-on industry experience, we’ve helped customers in sectors from energy to wastewater treatment streamline their maintenance workflows. A well-maintained Flange Immersion Heater not only runs longer—it runs safer, more efficiently, and ultimately supports the productivity of your entire operation. If you’re looking to optimize system performance and reduce lifecycle costs, we’re here to provide the technical support and custom solutions you need.

English

English русский

русский Français

Français Español

Español عربى

عربى