The Single-Ended Tubular Heater is a versatile and efficient heating solution designed for a wide ra...

Electric Heating Elements Manufacturers

-

-

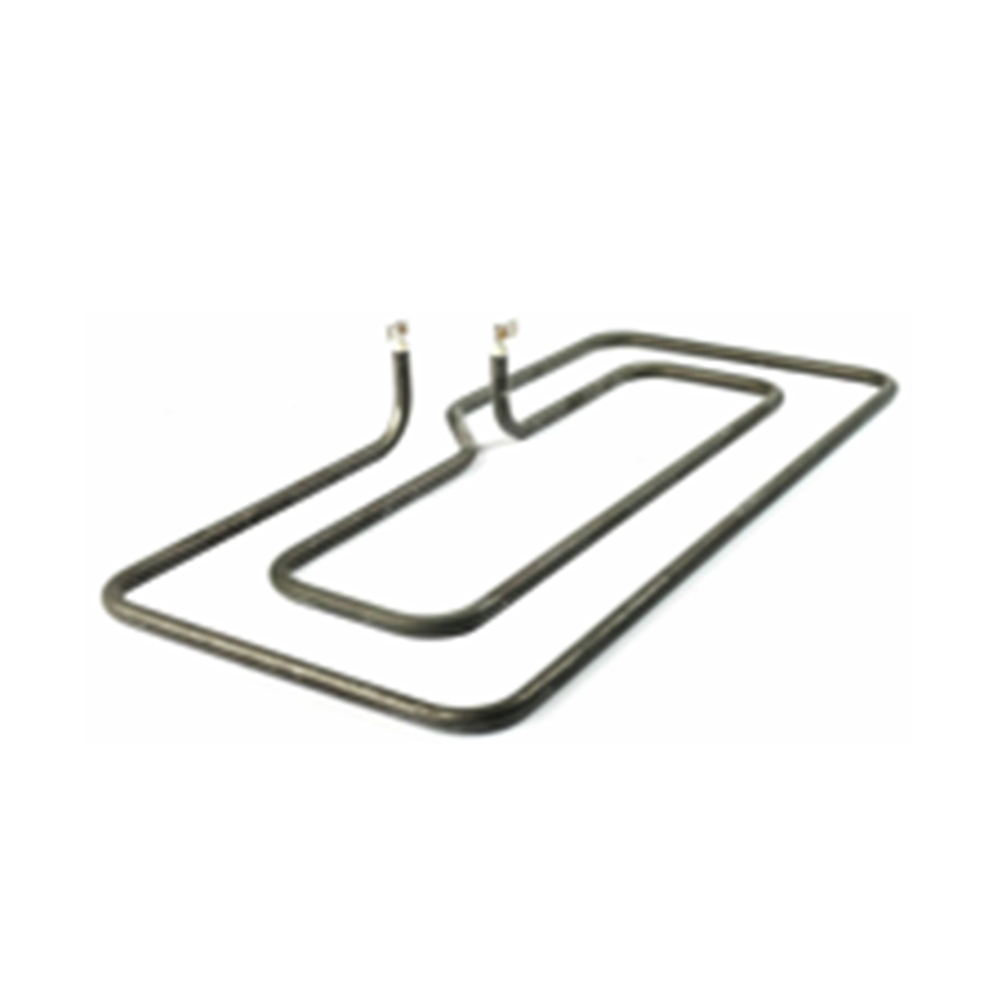

Heavy Duty Industrial Tubular Heater

Heavy Duty Industrial Tubular HeaterHeavy Duty Industrial Tubular Heater is a durable and versatile heating solution designed for high-p...

-

High Temperature Industrial Electric Heater

High Temperature Industrial Electric HeaterHigh-Temperature Industrial Electric Heater is a robust and reliable solution designed for demanding...

-

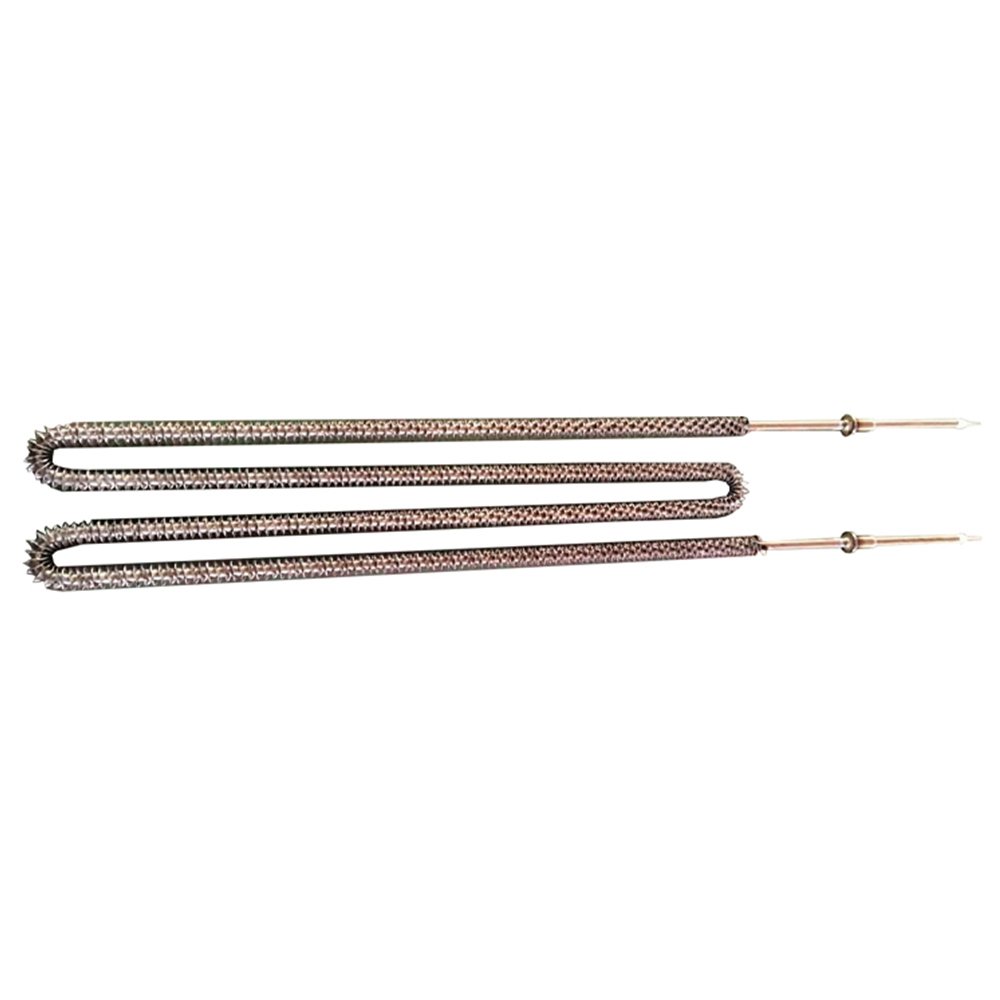

Finned Tubular Heating Element for Heating Premises

Finned Tubular Heating Element for Heating PremisesFinned Tubular Heating Elements are advanced heating solutions designed to maximize heat transfer in...

-

Long Life Ribbed Tubular Heater

Long Life Ribbed Tubular HeaterRibbed Tubular Heaters are advanced heating solutions designed to outperform standard tubular heater...

-

Ribbed Tubular Heating Element with Electro Galvanized Steel Fins

Ribbed Tubular Heating Element with Electro Galvanized Steel FinsCustomized Ribbed Tubular Heating Element is a highly versatile and durable heating solution designe...

-

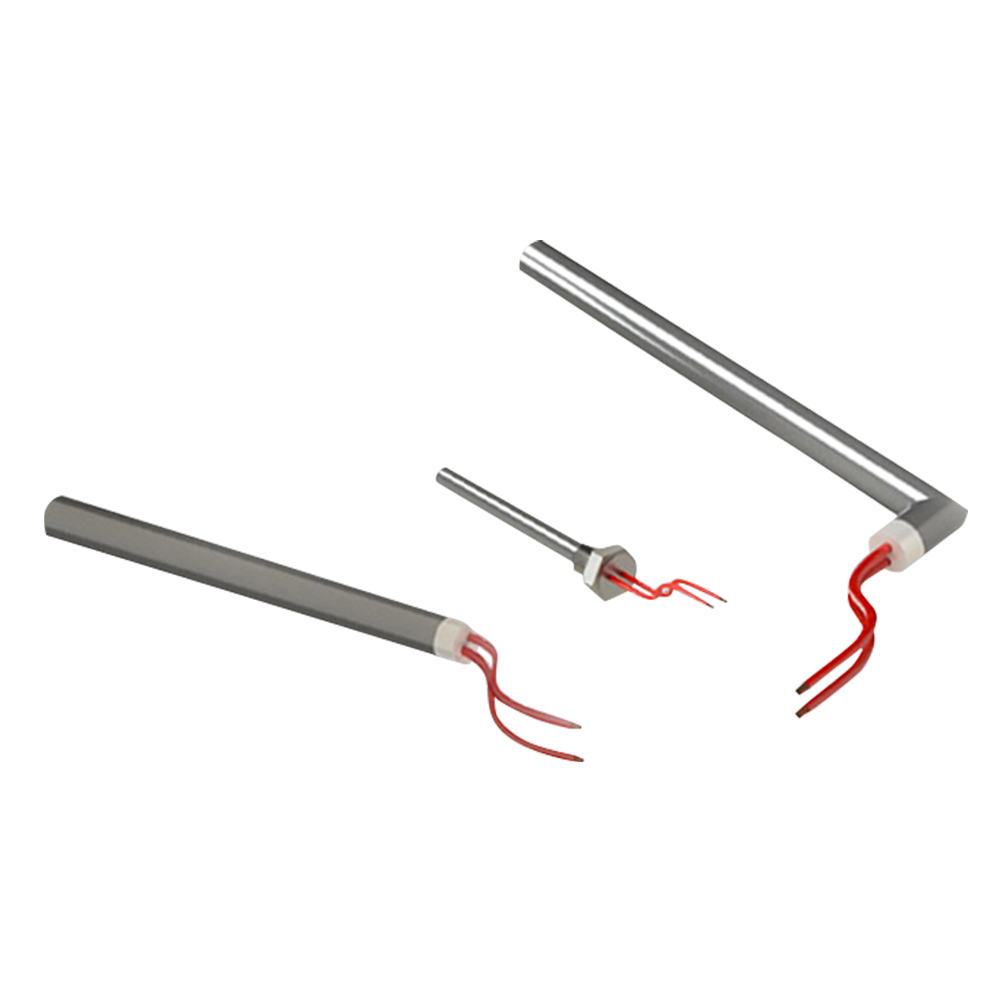

Small Size Industrial Tubular Heater

Small Size Industrial Tubular HeaterSmall Size Industrial Tubular Heater is a compact yet powerful heating solution designed for versati...

-

Spiral Tubular Heating Element

Spiral Tubular Heating ElementSpiral Tubular Heating Element is a highly durable and versatile heating solution, designed to meet ...

Heating elements are the core components of industrial and commercial heating systems, designed to convert electrical energy into heat efficiently and reliably. These elements are widely used in applications such as process heating, HVAC systems, water heating, and industrial equipment, providing precise and consistent temperature control.

Constructed from high-performance materials like nickel-chromium alloys, stainless steel, or ceramic, heating elements are engineered to withstand temperatures, high watt densities, and challenging environments. They are available in various forms, including tubular, cartridge, strip, and flexible designs, to suit diverse application requirements.

Modern heating elements often incorporate advanced features like rapid heating capabilities, uniform heat distribution, and integrated temperature sensors, ensuring performance and energy efficiency. Whether for industrial processes, residential appliances, or specialized equipment, heating elements deliver durable and customizable solutions for effective thermal management.

Jiangsu Weineng Electric Co.,Ltd established in April 23rd,2009, is a professional manufacturer engaged in the research, development, production, sale and service of Electric Heaters,Electric Heat Tracing Cable and Control system for industry.

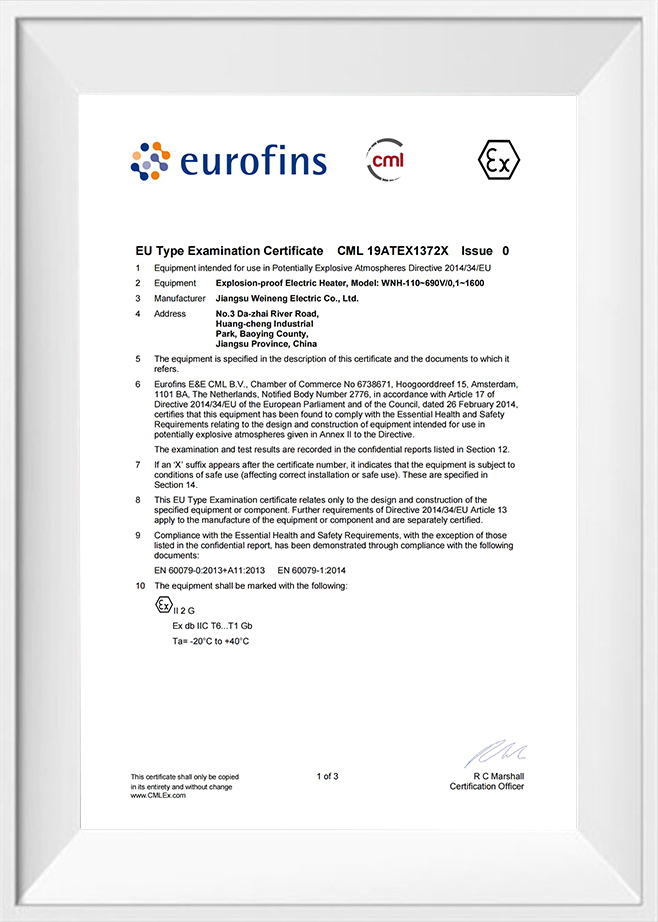

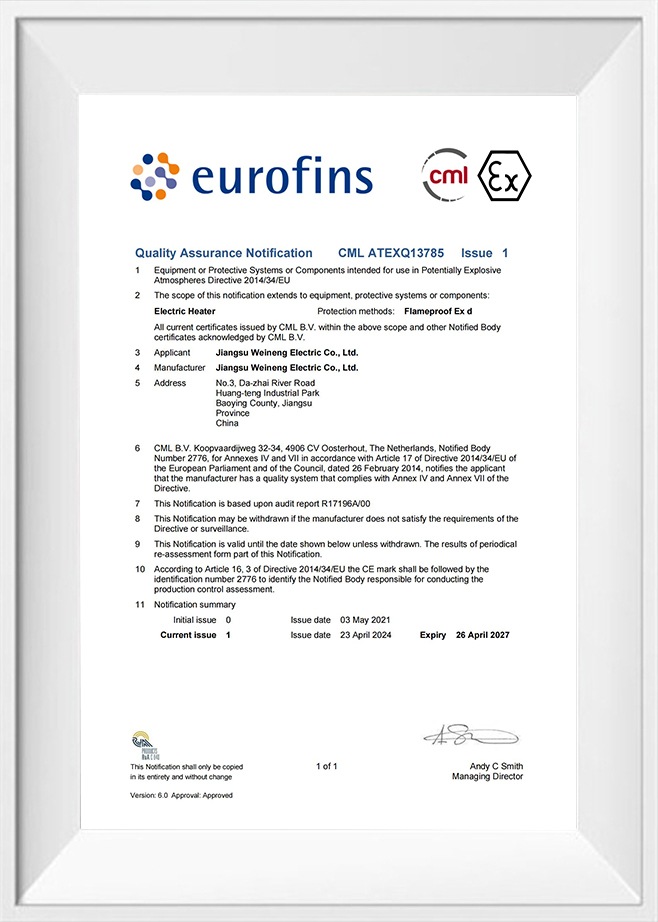

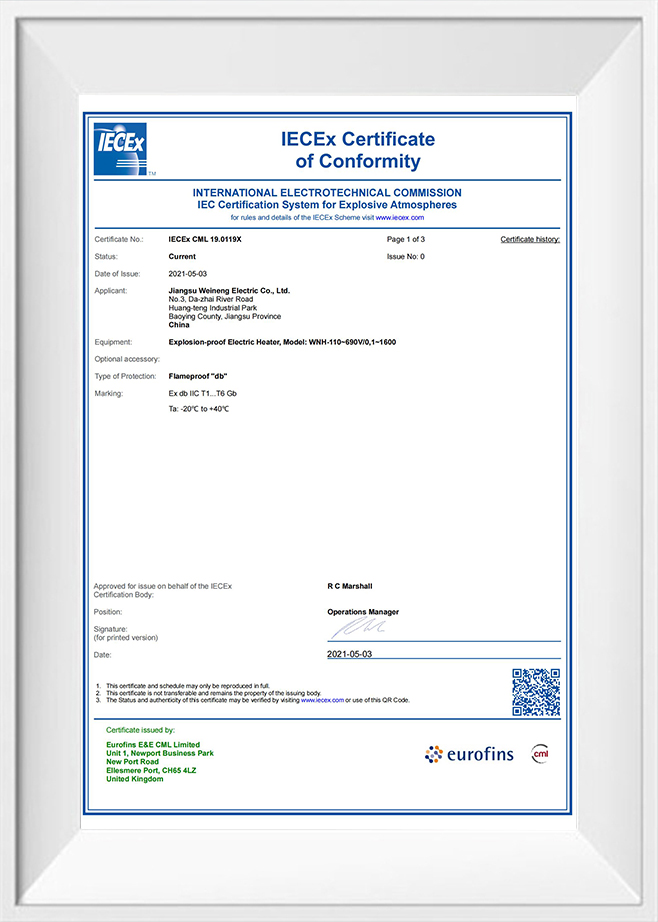

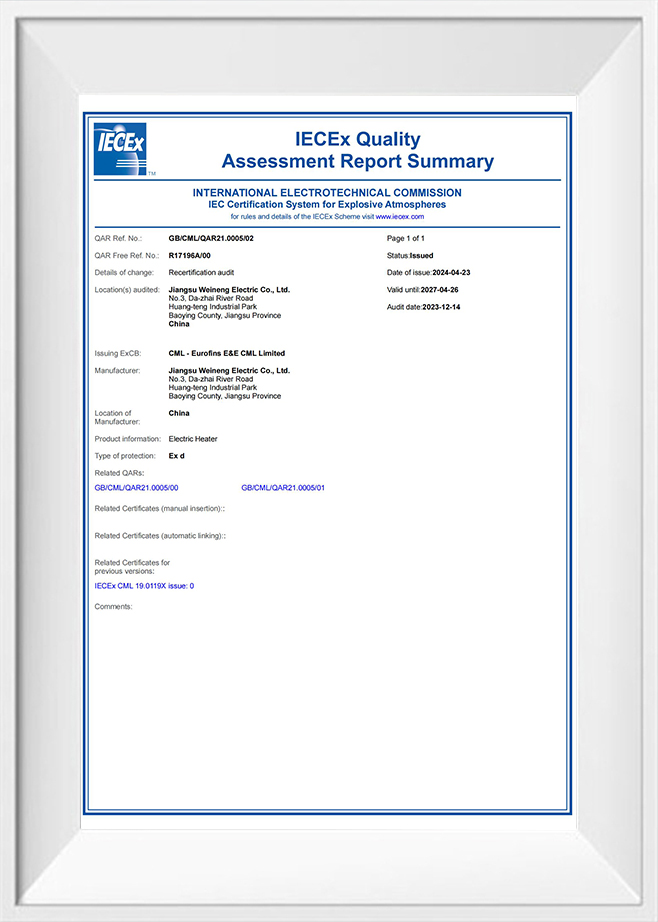

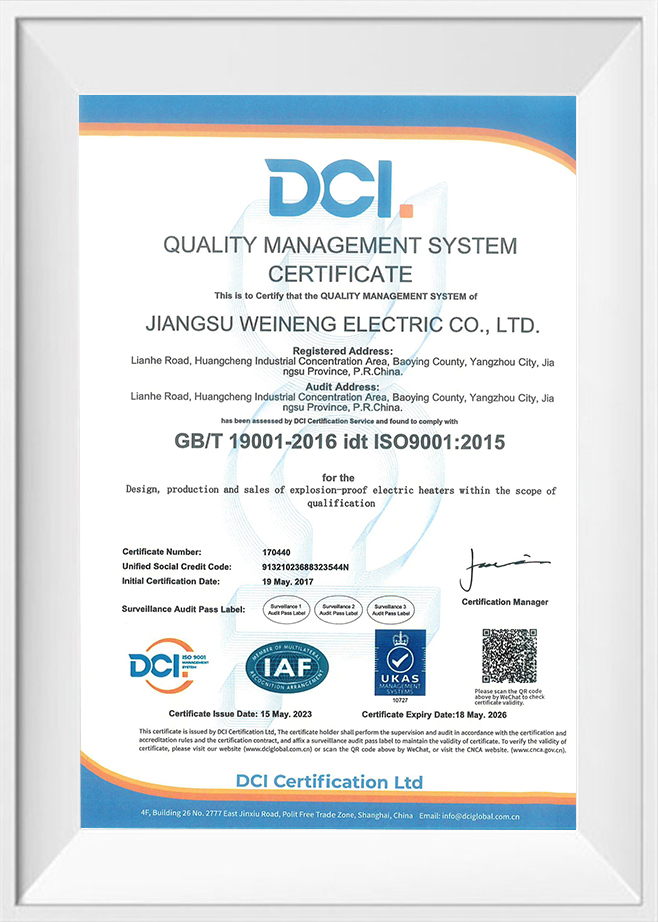

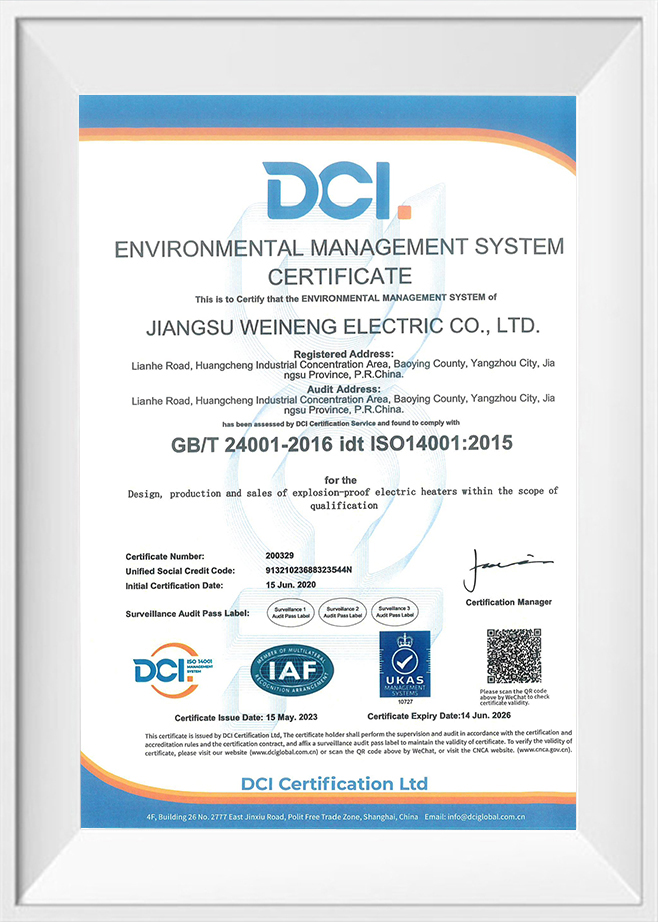

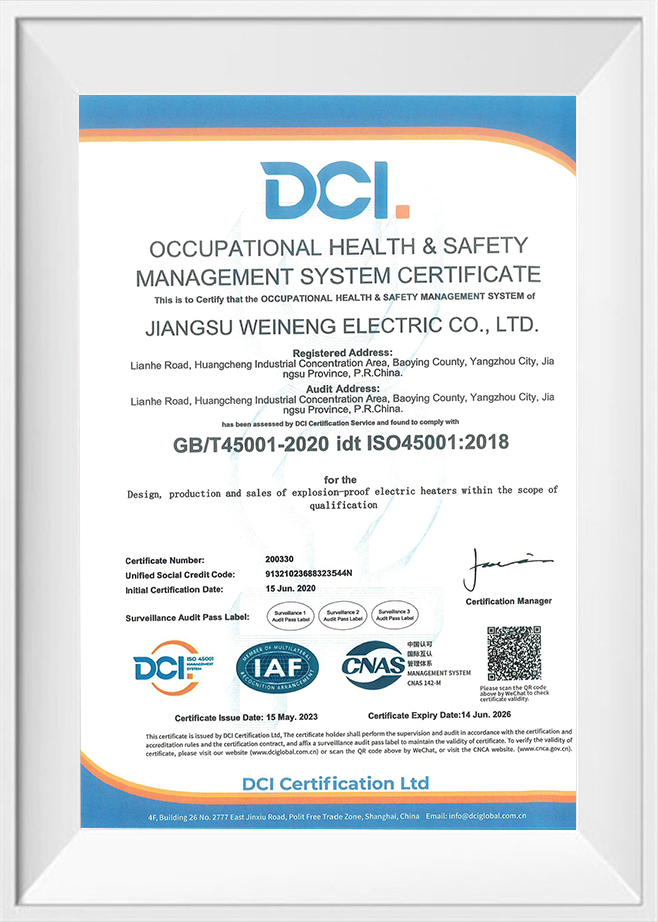

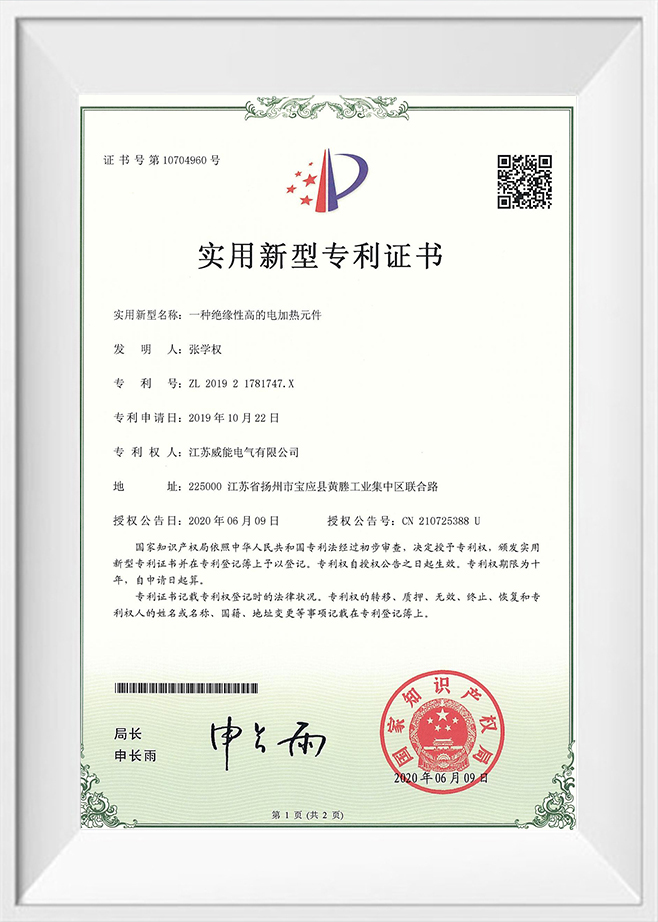

As China Tubular Heaters Manufacturers and Tubular Heater Factory, We are located in Baoying County,Jiangsu Province with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including power filling machine,electric pressure test pump,gauge lathe,LCD spot welding machine,drying cabinet,cleaning machine,dry sand blasting machine,automatic pipebender,digital multimeter,insulation resistance meter,voltage-resistant tester. Our company insist in technological innovation,we have 3 professors of engineering and dozens of young engineers with rich experience to orgonized a professional engineering team.We cooperate with universities and academies to research and develop new product. In addition, we have obtained IEcEx,Attex,ISO certificates.Selling well in all cities and provinces around China, We offer Custom Tubular Heater. our products are also exported to clients in such countries and regions as Middle East,Southeast Asia ,America and Europe. We also welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.Learn about our industry exhibition information and recent events in our company.

-

Explosion Proof Electrical Connectors: Selection & Safety Guide

What Explosion Proof Electrical Connectors Actually Do Explosion proof electrical connectors are not designed to prevent an internal spark or arc — t...25 -

Air Duct Heaters: Efficient HVAC Heating Solutions

Air Duct Heaters Deliver Targeted, Energy-Efficient Heating Directly Within HVAC Systems Air duct heaters are electric heating elements installed ins...19 -

Air Duct Heaters for Efficient HVAC Temperature Control

Air Duct Heaters as a Practical Heating Solution Air duct heaters are an efficient and controllable way to raise or stabilize air temperature directl...09 -

Electric Immersion Heater: Types, Uses & Safety Tips

Electric Immersion Heater: Quick Overview and Conclusion Electric immersion heaters are highly efficient devices for heating liquids directly in tank...05 -

Can Upgrading Process Heaters Boost Manufacturing Competitiveness?

The Role of Process Heaters in Modern Manufacturing Process heaters are critical components in industrial operations, providing the controlled heat ne...30

Understanding Heating Element Materials: How Composition Impacts Efficiency and Application Suitability

When it comes to the performance and reliability of any electric heating element, the choice of material is far from a trivial decision—it forms the backbone of how well the component will function under specific operational conditions. Whether it’s a tubular heater used in heavy-duty industrial machinery or a compact strip heater integrated into a home appliance, the internal structure and elemental composition are decisive factors in ensuring long-term thermal efficiency and mechanical durability.

The most commonly used materials in heating element manufacturing are nickel-chromium alloys, stainless steel, and ceramics. Nickel-chromium, often referred to as nichrome, offers excellent resistance to oxidation and maintains stable electrical resistance even at elevated temperatures. This makes it an ideal core for many electric heating elements, especially where uniform and high-temperature heating is required over extended periods. Meanwhile, stainless steel variants provide corrosion resistance and mechanical strength, making them suitable for humid environments or applications where exposure to chemicals is a concern.

Ceramic materials, although more fragile, serve an important role in certain specialized configurations, particularly where electrical insulation is critical or where radiant heating is preferred. Their insulating properties help prevent energy losses and support higher thermal efficiencies in compact designs. Advanced ceramics also allow for higher watt densities without compromising safety, which is crucial for modern systems that demand compactness without performance loss. These materials often appear in cartridge and infrared heating elements tailored for precise thermal control.

The selection process doesn’t end with just choosing between nichrome and stainless steel. Different grades and alloying elements can significantly impact performance characteristics such as maximum operating temperature, flexibility, resistance to thermal cycling, and even weight. For example, in high-vibration industrial environments, certain grades of stainless steel can reduce mechanical fatigue over time, preventing premature failure. Similarly, nickel-rich alloys offer better creep resistance, crucial in continuous-use applications like ovens, plastic processing, or chemical reactors.

A well-designed tubular heater, for instance, relies not only on its shape or structure but on the specific interaction between its sheathing material and the internal heating wire. This synergy determines how evenly heat is transferred and how efficiently the system can reach and maintain target temperatures. Materials with poor thermal conductivity or mismatched expansion rates can introduce hot spots or stress points, leading to reduced efficiency and potential safety risks. For customers seeking performance, longevity, and reduced downtime, understanding these material dynamics is an investment in smarter sourcing.

From a manufacturer’s perspective, material choice is also closely tied to regulatory compliance and customization potential. Applications in the food, medical, and aerospace sectors, for instance, require materials that meet strict hygiene or safety standards. As a result, we not only test our heating elements for operational reliability but also ensure our materials meet global compliance requirements. This blend of precision engineering and high-quality materials is what sets apart a dependable electric heating element from a short-lived or underperforming one.

The material composition of a heating element isn't just a technical detail—it's a critical factor that defines its performance, safety, and application range. Whether you're designing a new product or sourcing for an existing system, partnering with a knowledgeable supplier who understands material science can make all the difference. With over a decade of experience in manufacturing and customizing tubular heaters and other industrial heating solutions, we help businesses find the right material match for their specific thermal challenges.

English

English русский

русский Français

Français Español

Español عربى

عربى