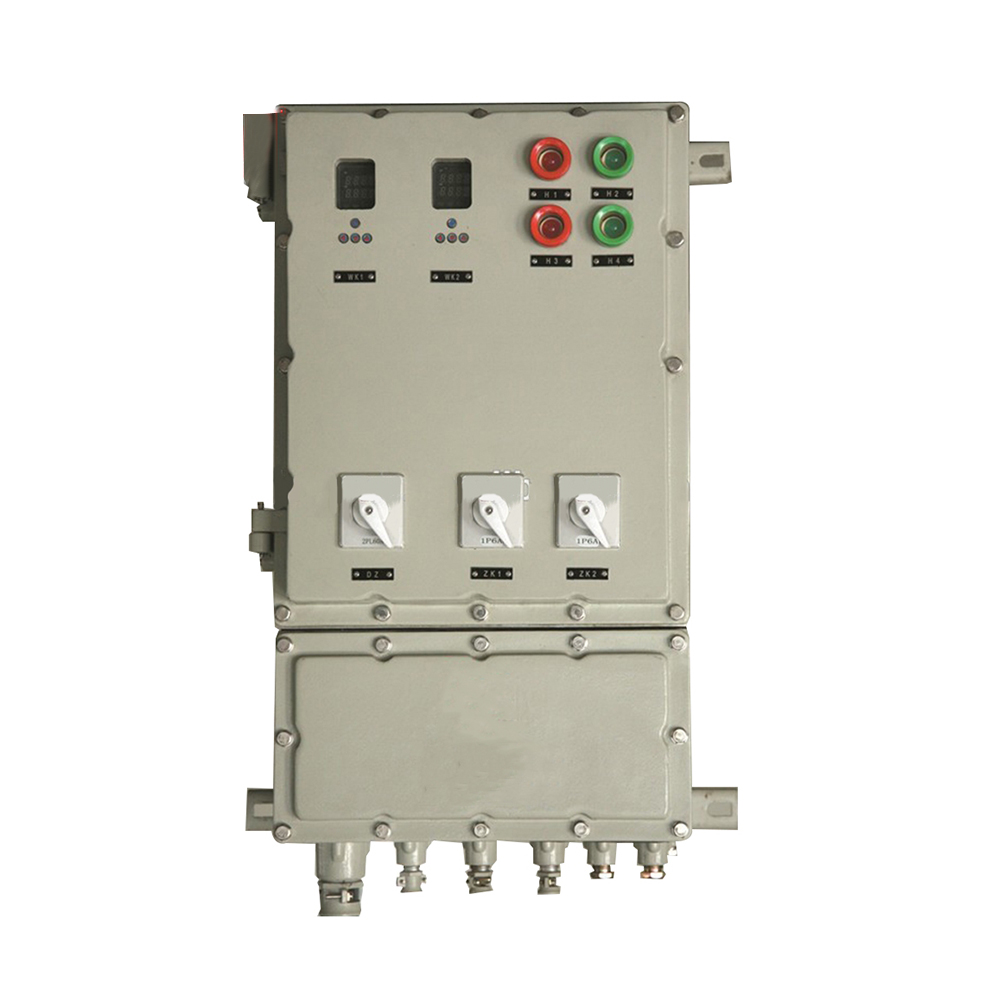

Flameproof Control Cabinet for Industrial Electric Heaters is a specialized solution designed to ens...

Industrial Electric Control Cabinet Manufacturers

-

-

Non-Explosion Control Cabinet for Industrial Electric Heater

Non-Explosion Control Cabinet for Industrial Electric HeaterNon-Explosion Control Cabinet for Industrial Electric Heaters is a versatile and efficient solution ...

-

Indoor/Outdoor Use Industrial Electric Control Cabinet

Indoor/Outdoor Use Industrial Electric Control CabinetA customized Industrial Electric Control Cabinet is a tailored solution designed to manage and contr...

-

Multiple Sealing Explosion Proof Control Cabinet

Multiple Sealing Explosion Proof Control CabinetMultiple Sealing Explosion Proof Control Cabinet is a highly specialized and robust solution designe...

-

Stainless Steel Non-explosion-proof Electric Control Cabinet

Stainless Steel Non-explosion-proof Electric Control CabinetStainless Steel Electric Control Cabinet is a durable and versatile solution designed to enhance ind...

-

Aluminum Alloy Die-casting Control Cabinet for Air Duct Heater

Aluminum Alloy Die-casting Control Cabinet for Air Duct HeaterControl Cabinet for Air Duct Heater is a robust and customizable solution designed to provide precis...

Control systems are integral components of modern industrial processes, designed to monitor, regulate, and optimize the operation of heating, cooling, and other critical systems. These systems are essential in ensuring precise control over variables such as temperature, pressure, flow rate, and humidity, providing enhanced efficiency, safety, and reliability across a wide range of industries, including manufacturing, energy, and chemical processing.

Control systems typically consist of sensors, controllers, actuators, and communication interfaces, which work together to maintain desired operational parameters. Advanced systems incorporate programmable logic controllers (PLCs), touch-screen interfaces, and real-time monitoring to enable seamless integration and intuitive control.

With features like automated fault detection, predictive maintenance, and energy optimization, modern control systems not only improve system performance but also reduce operational costs and downtime. Whether for simple applications or complex industrial processes, control systems provide customizable, scalable, and cost-effective solutions for efficient process management.

Jiangsu Weineng Electric Co.,Ltd established in April 23rd,2009, is a professional manufacturer engaged in the research, development, production, sale and service of Electric Heaters,Electric Heat Tracing Cable and Control system for industry.

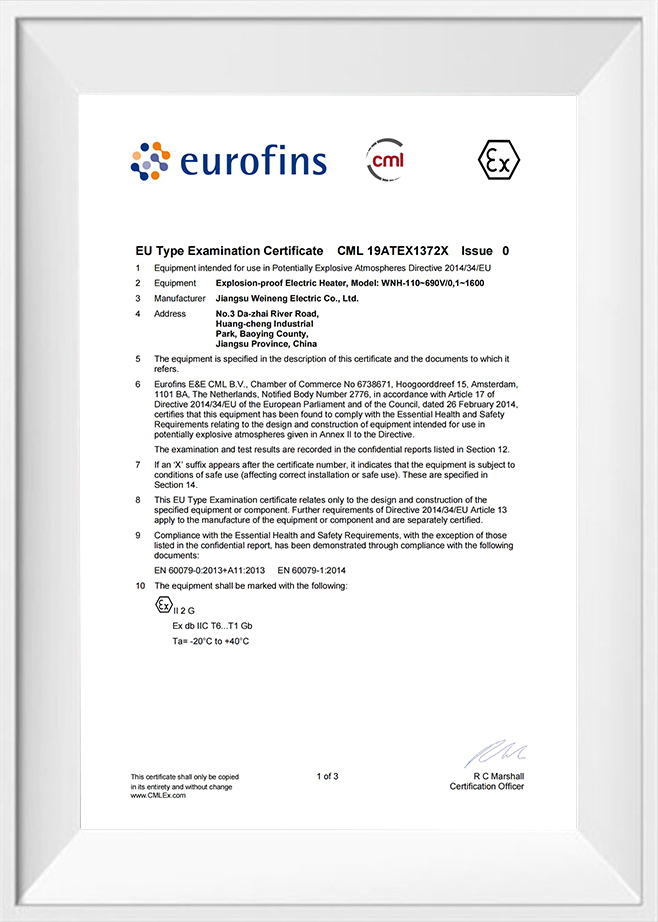

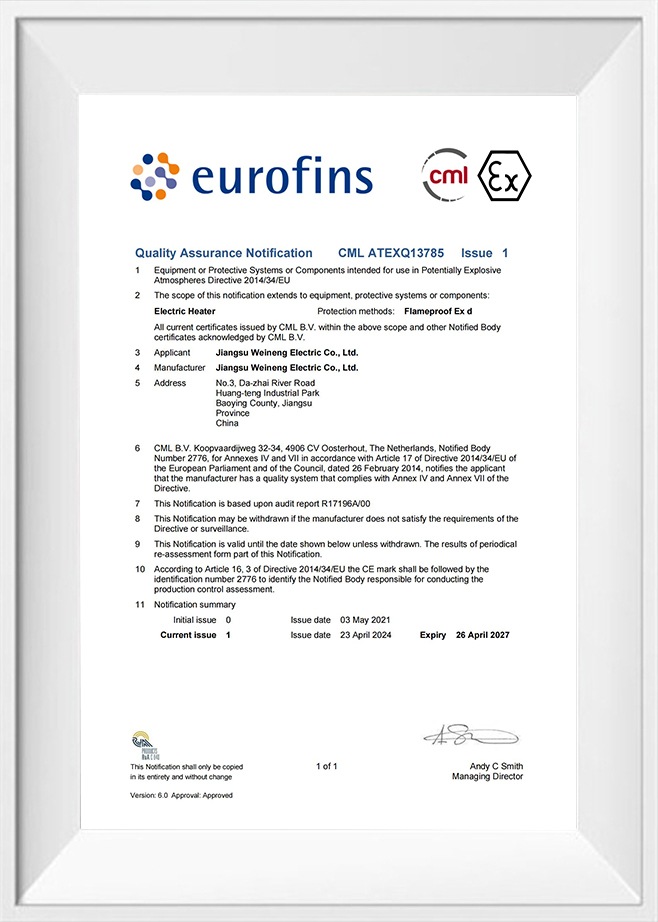

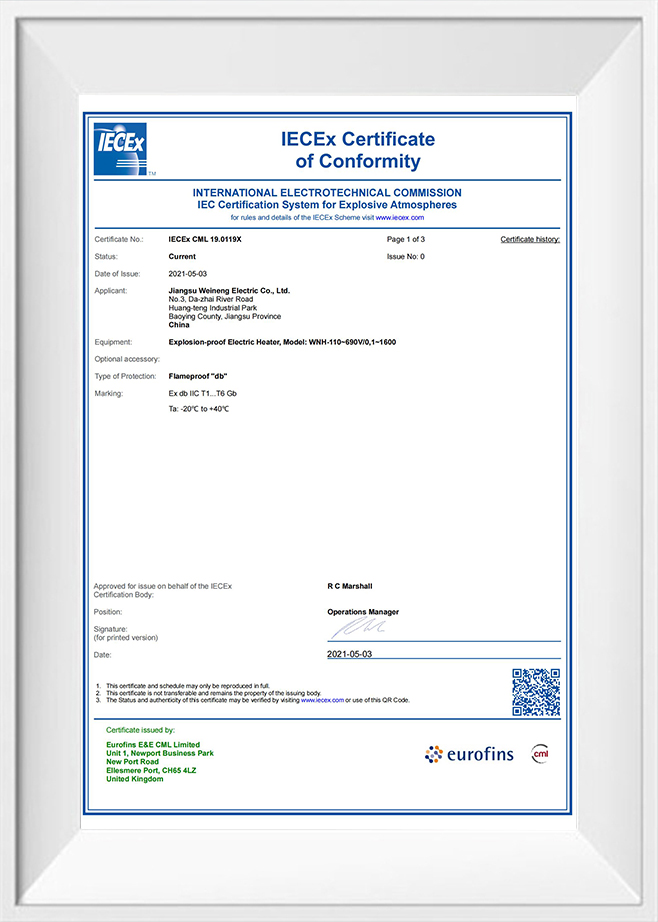

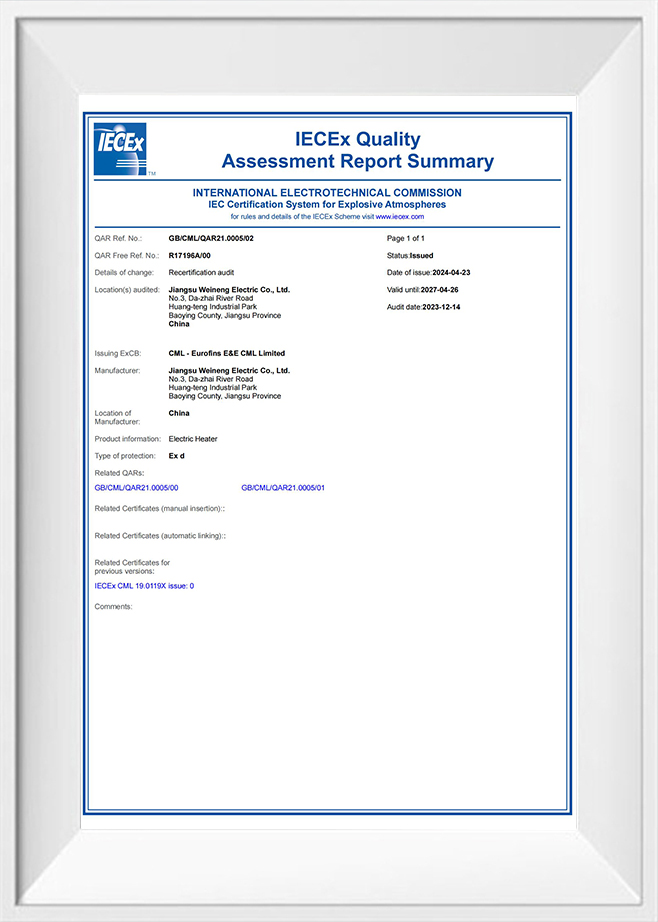

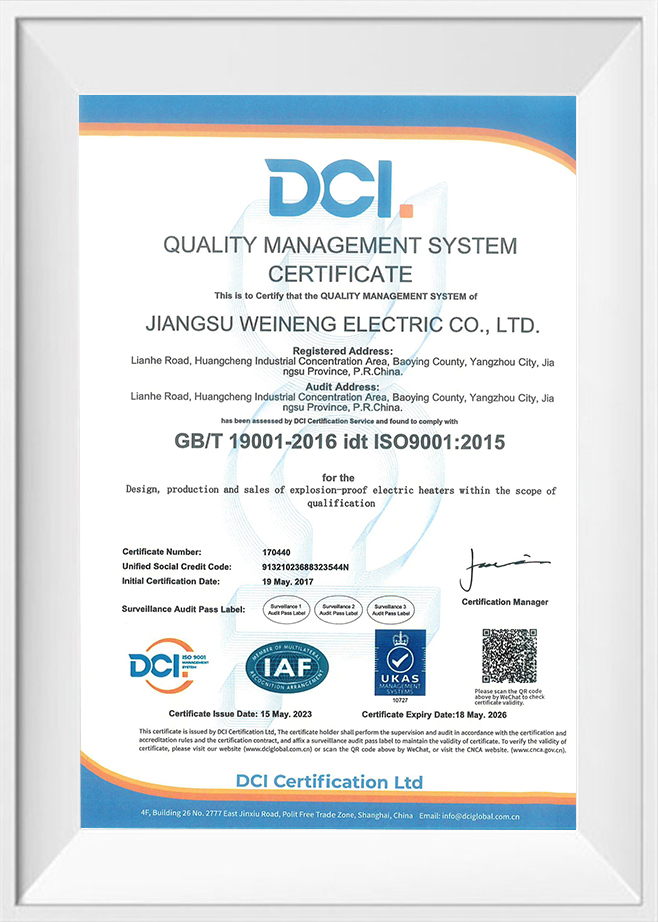

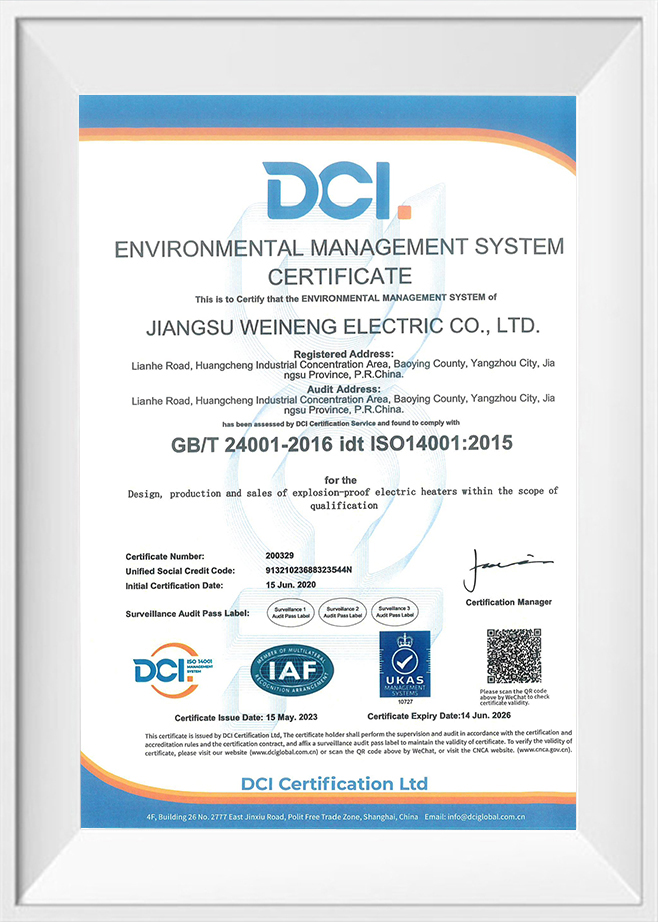

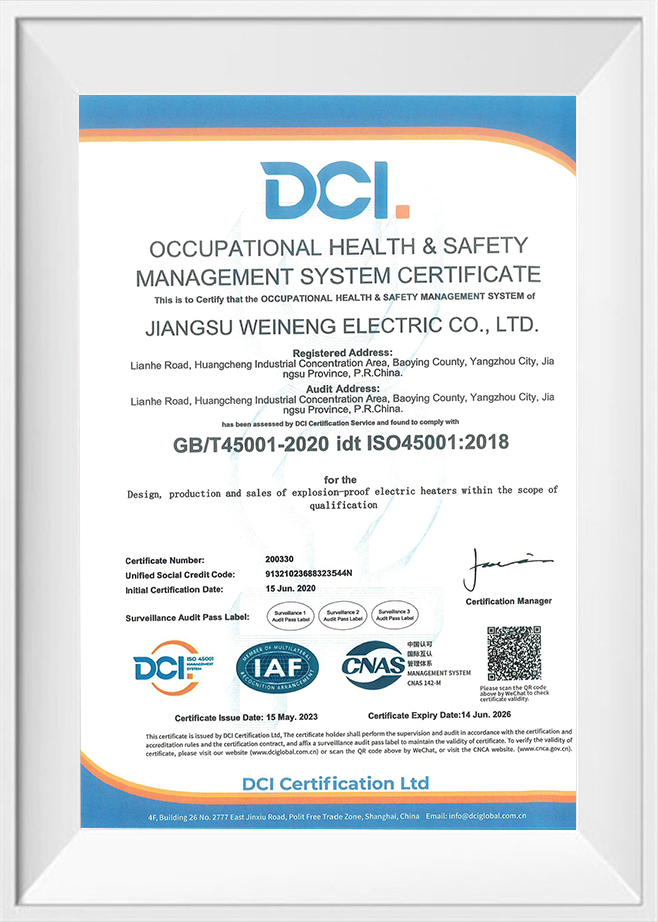

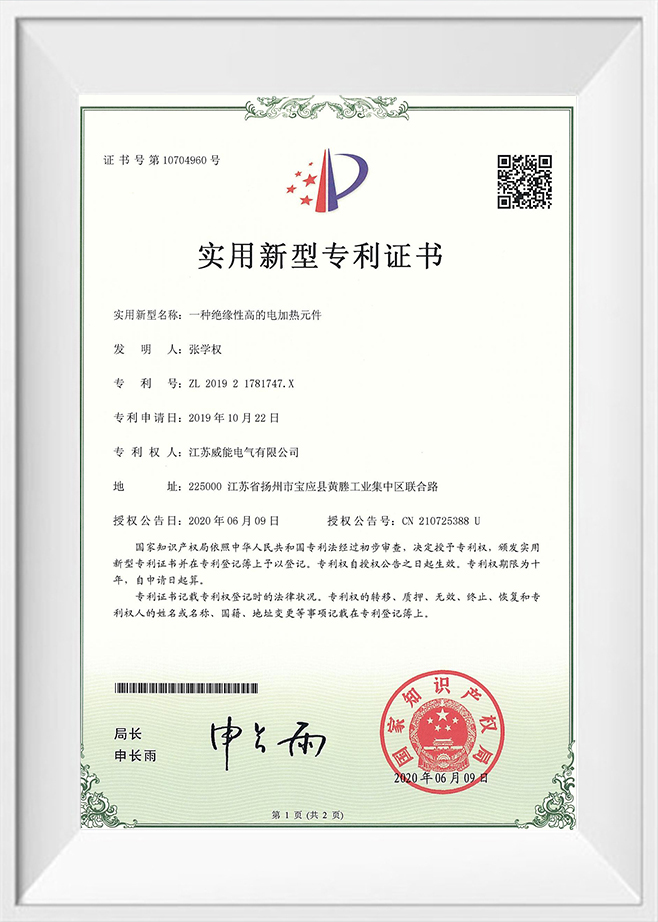

As China Industrial Electric Heater Control Cabinet Manufacturers and Industrial Electric Heater Control Cabinet Factory, We are located in Baoying County,Jiangsu Province with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including power filling machine,electric pressure test pump,gauge lathe,LCD spot welding machine,drying cabinet,cleaning machine,dry sand blasting machine,automatic pipebender,digital multimeter,insulation resistance meter,voltage-resistant tester. Our company insist in technological innovation,we have 3 professors of engineering and dozens of young engineers with rich experience to orgonized a professional engineering team.We cooperate with universities and academies to research and develop new product. In addition, we have obtained IEcEx,Attex,ISO certificates.Selling well in all cities and provinces around China, We offer Custom Control Cabinet for Indutrial Electric Heater. our products are also exported to clients in such countries and regions as Middle East,Southeast Asia ,America and Europe. We also welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.Learn about our industry exhibition information and recent events in our company.

-

Explosion Proof Electrical Connectors: Selection & Safety Guide

What Explosion Proof Electrical Connectors Actually Do Explosion proof electrical connectors are not designed to prevent an internal spark or arc — t...25 -

Air Duct Heaters: Efficient HVAC Heating Solutions

Air Duct Heaters Deliver Targeted, Energy-Efficient Heating Directly Within HVAC Systems Air duct heaters are electric heating elements installed ins...19 -

Air Duct Heaters for Efficient HVAC Temperature Control

Air Duct Heaters as a Practical Heating Solution Air duct heaters are an efficient and controllable way to raise or stabilize air temperature directl...09 -

Electric Immersion Heater: Types, Uses & Safety Tips

Electric Immersion Heater: Quick Overview and Conclusion Electric immersion heaters are highly efficient devices for heating liquids directly in tank...05 -

Can Upgrading Process Heaters Boost Manufacturing Competitiveness?

The Role of Process Heaters in Modern Manufacturing Process heaters are critical components in industrial operations, providing the controlled heat ne...30

Unlocking Predictive Maintenance Potential in Industrial Control Systems for Greater Efficiency and Uptime

Predictive maintenance is rapidly becoming a cornerstone of modern industrial automation strategies, and its integration into control systems marks a major shift in how manufacturers and plant operators manage operational health. Rather than relying solely on scheduled inspections or reactive repairs, predictive maintenance leverages real-time data collected through sensors and control logic to forecast failures before they happen. This capability, once considered cutting-edge, is now increasingly accessible and practical, especially for industries managing high-demand equipment like the industrial electric heater.

At the heart of this transformation is the control system itself, acting as the central nervous system that ties together temperature sensors, vibration monitors, and current analyzers. When integrated properly, these elements continuously feed operational data into the Indutrial Electric Heater Control Cabinet, where intelligent algorithms can identify deviations from expected patterns. For example, a gradual increase in energy consumption without a corresponding rise in output might indicate resistance coil degradation—long before complete failure occurs.

Such proactive monitoring requires a well-designed infrastructure. Systems equipped with programmable logic controllers (PLCs) and SCADA platforms can be programmed to analyze trends and issue alerts when thresholds are breached. More advanced setups incorporate cloud analytics or edge computing to reduce latency in decision-making, especially in facilities where downtime directly translates to production losses. For manufacturers using electric process heating systems, this early detection is especially valuable, as downtime for equipment like indutrial electric heaters can disrupt entire production lines.

However, it's not just about sensors and software; the real value comes from knowing how to interpret the data. A control system must be configured with a clear understanding of the equipment’s operational profile, environmental variables, and failure modes. Over time, the accumulated data enables smarter decision-making and the refinement of maintenance schedules based on actual Industrial Electric Control Cabinet conditions rather than assumptions. This results in lower maintenance costs, improved safety, and longer asset life—all while minimizing unscheduled interruptions.

Implementing predictive maintenance isn’t a plug-and-play solution—it requires experience, customization, and collaboration between control system engineers, maintenance teams, and process operators. That’s where an experienced manufacturer adds real value. By understanding both the electrical characteristics of the equipment and the unique requirements of each industrial process, we can tailor control solutions that not only manage heating operations precisely but also provide actionable diagnostics that evolve with your operation.

Many of our clients, especially those operating in high-temperature or continuous production environments, have seen significant ROI after upgrading to predictive-enabled systems. From control cabinets for industrial electric heaters to full-scale automation platforms, the integration of condition monitoring and fault prediction has transformed their maintenance models into a competitive advantage. The key lies in leveraging both technology and domain expertise to deliver systems that are not only technically advanced but also practical and dependable.

As industrial demands grow more complex, so does the need for intelligent control strategies that adapt to real-world conditions. Predictive maintenance isn’t just a trend—it’s a strategic tool for ensuring operational resilience and efficiency. With the right design and support, it can be seamlessly woven into your existing infrastructure, bringing long-term reliability and cost savings to the forefront of your operations.

English

English русский

русский Français

Français Español

Español عربى

عربى