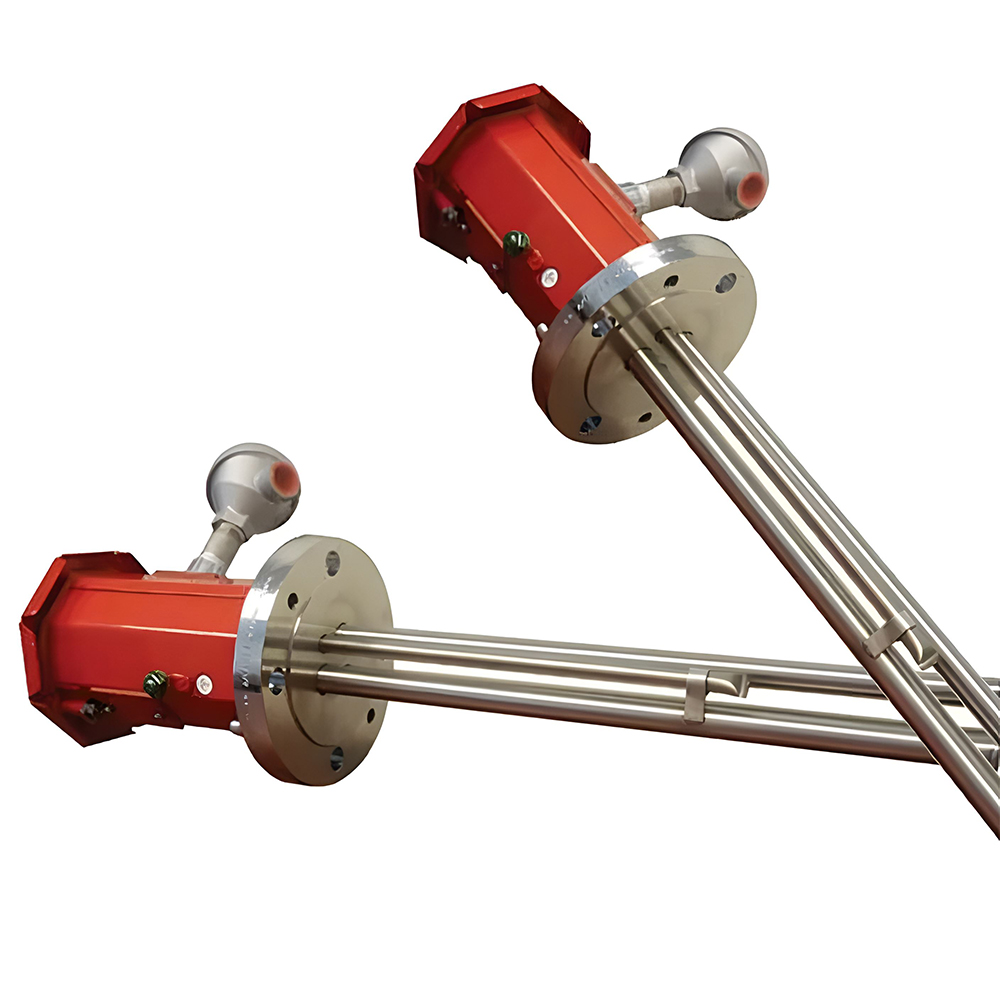

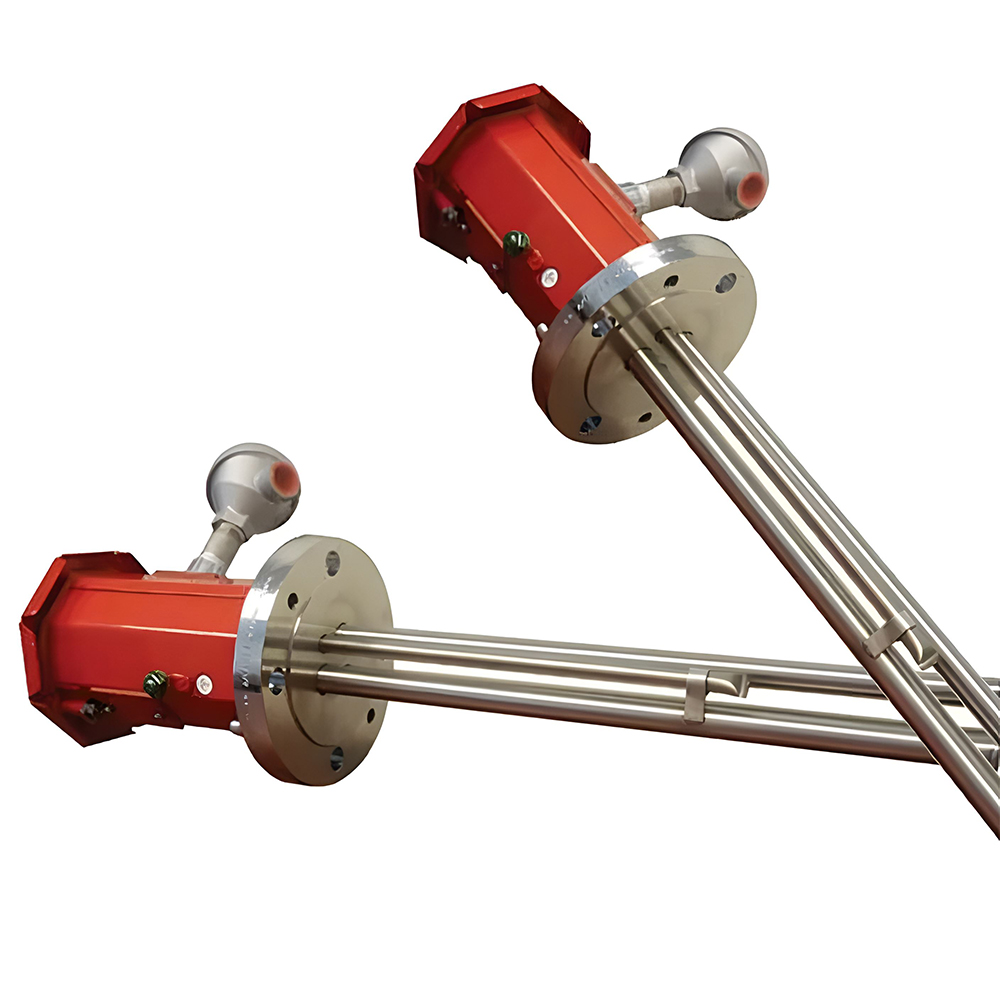

Introduction to Explosion Proof Flange Heaters

Explosion proof flange heaters are advanced industrial heating devices designed for safe operation in hazardous environments. Unlike standard heaters, these units prevent ignition of flammable gases, vapors, or dust, ensuring a reliable and safe heat source. Widely used in chemical, oil, and gas industries, explosion proof flange heaters combine robust design, compliance with safety regulations, and superior performance to meet the demands of critical industrial processes.

Design and Construction Features for Reliability

The reliability of explosion proof flange heaters comes from their carefully engineered construction and high-quality components. Key design elements include:

Flanged Mounting for Secure Installation

The flanged design allows secure attachment to tanks, vessels, or pipelines. This ensures tight sealing and uniform heat distribution, critical for industrial heating applications. Flanged connections prevent leakage and improve operational reliability compared to standard heaters.

Explosion Proof Enclosure

The electrical components are housed in a heavy-duty explosion proof enclosure that contains sparks or high-temperature surfaces. Certified by ATEX, IECEx, or UL, these safe industrial heaters operate reliably even in high-risk zones, protecting both personnel and equipment.

High-Quality Heating Elements

Corrosion-resistant heating elements, such as Incoloy or stainless steel, provide rapid heat-up and durability. These elements ensure consistent heat transfer, long service life, and reliable performance in hazardous environment heating where standard heating elements often fail.

Safety Advantages Over Standard Heaters

Safety is the key advantage of explosion proof flange heaters. Compared to standard heaters, they reduce the risk of fire or explosion and protect personnel in hazardous zones.

Ignition Prevention in Hazardous Areas

By containing sparks and high temperatures within the enclosure, explosion proof heaters prevent ignition of flammable gases or dust. Standard heaters lack this protection, making them unsafe for critical industrial applications.

Temperature Control and Overheat Protection

Integrated temperature sensors and overheat protection ensure the heater operates within safe limits. This feature maintains process safety and protects equipment, which is crucial in hazardous environment heating.

Compliance with Safety Standards

Explosion proof flange heaters meet strict international standards for safe industrial heaters. Standard heaters often do not comply with these regulations, limiting their use in high-risk environments.

Performance and Reliability Benefits

Explosion proof flange heaters provide consistent, reliable performance, which is essential for critical industrial processes:

Consistent Heat Distribution

High-quality heating elements and flanged mounting provide uniform heat transfer, ensuring precise temperature control in chemical tanks, pipelines, or storage vessels. Reliable heat distribution is a key factor distinguishing explosion proof flange heaters from standard industrial heaters.

Durability in Harsh Conditions

Corrosion-resistant materials and robust enclosures allow these heaters to withstand moisture, chemical exposure, and high ambient temperatures, ensuring long-term reliability where standard heaters may fail.

Reduced Maintenance and Downtime

Durable construction and high-quality components reduce failure rates and maintenance requirements. This minimizes downtime and increases operational efficiency compared to standard heaters.

Applications in Industrial Environments

Explosion proof flange heaters are widely used in various hazardous industrial environments:

- Chemical processing tanks requiring precise and safe temperature control.

- Oil and gas pipelines, vessels, and storage units in flammable zones.

- Food, pharmaceutical, and beverage processing with strict hygiene and safety standards.

- Paint, coatings, and adhesives production needing consistent industrial heating.

- Wastewater treatment plants and industrial boilers operating in hazardous zones.

Comparison With Standard Heaters

A comparison highlights the advantages of explosion proof flange heaters:

| Feature |

Explosion Proof Flange Heater |

Standard Heater |

| Safety in Hazardous Areas |

High, certified for flammable environments |

Low, risk of ignition |

| Durability |

High, corrosion-resistant and heat-proof |

Medium, prone to environmental damage |

| Maintenance |

Low, minimal downtime |

High, frequent repairs required |

| Temperature Control |

Precise and uniform |

Variable, may be uneven |

| Regulatory Compliance |

ATEX, IECEx, UL certified |

Limited or non-compliant |

Conclusion

Explosion proof flange heaters offer superior reliability, safety, and performance compared to standard industrial heaters. With flanged mounting, robust enclosures, high-quality heating elements, and built-in safety features, these safe industrial heaters are ideal for hazardous environments. They provide consistent heat, reduce downtime, and comply with strict industrial safety standards, ensuring long-term operational efficiency and protection in critical industrial applications.

English

English русский

русский Français

Français Español

Español عربى

عربى